Guide to Construction Estimating [Types, Tips, and Best Practices]

![Guide to Construction Estimating [Types, Tips, and Best Practices]](https://buildern.com/resources/wp-content/uploads/2025/08/Construction_Estimating-768x501.jpg)

In the construction project, nothing moves forward without numbers. Detailed estimating of the project costs is the secret to successful construction.

It’s challenging to consider every detail for one project, but for multiple jobs, it takes even more effort. Each may have its own level of complexity and unique requirements.

One thing in common for all is to stay on budget within the deadline and ensure that the work turns into a profit. None of this is possible without accurate construction estimating.

Our guide will discuss everything you need to know about estimating that not only keeps clients within budget but also protects the general contractor’s financial goals.

Table of Contents

- What is Construction Estimating?

- Key Challenges in Estimation

- Key Elements of a Construction Estimate

- Types of Construction Estimates

- Step-by-Step Construction Estimating Process

- Best Practices for Accurate Construction Estimating

What is Construction Estimating?

It is the process of forecasting the total cost required to complete a construction project. This is about calculating all expenses before the job starts.

The main goal is to provide the most detailed plan possible. Think of it as a financial blueprint. Without it, you’re essentially building blind. A solid estimate is about providing a clear plan that makes a project both achievable and profitable.

It also plays a big role in landing a project when a rough estimate becomes a polished proposal. An accurate estimate can be the deciding factor for a homeowner choosing between contractors. That’s why owners and contractors alike depend on estimates to guide a project from preconstruction to completion.

Construction estimating can be done by either a general contractor or a professional estimator. This depends on the company size and the projects it’s running. Some building firms hire or outsource a dedicated estimator who handles the job.

Why Accurate Estimates Matter

Inaccurate estimates can derail a project faster than any other unpredictable factors, such as weather. A well-prepared one ensures financial stability for a general contractor and strengthens client trust.

A clear estimate pays off after launching a project, as with the right numbers, it takes less effort and time to line up crews and order materials.

Key Challenges in Estimation

Doing calculations is not that easy, especially when there are some unpredictable points to consider. Let’s see which are the most important issues that may affect general contractors’ plans.

Market Fluctuations

One day, your material costs look solid. In several days, prices spike because of supply chain disruptions or market demand. The same applies to equipment prices. Limited access to necessary equipment or unexpected rental price increases can affect the costs. Suddenly, your carefully crafted estimate feels outdated, and you struggle to cover the gap.

Skilled Labor Problems

Good workers aren’t always easy to find. One of the hiring challenges the industry faces is labor shortages. Finding qualified workers at the right time and rate is a struggle. Besides, some tasks can require specialized skills that are hard to source.

Scope Creep

Clients change their minds. Besides, designs can change, the construction may expand, or unexpected site issues may pop up. Without tight control, these changes can snowball, driving costs and timelines beyond original plans.

Inaccurate Quantity Takeoff

Errors in measuring or counting materials and labor needs can throw off an entire estimate. Overlooking small details in the takeoff phase can lead to costly issues once construction is underway.

Key Elements of a Construction Estimate

Every solid estimate is based on some important elements that make a project happen. It includes the wages a general contractor pays the crew, equipment costs, and other expenses.

Add in a buffer for risks, and don’t forget the markup. When getting all these elements right from the beginning of the project, the general contractor can better plan the work. Let’s list all of them.

Direct Costs: These expenses refer to physical items like equipment rental and materials. Besides, they include costs that are tied to building the project, including wages of in-house workers, subcontractor fees, transportation of materials, etc.

Indirect Costs: They cover everything that supports the project but isn’t physically built into it. Those are site utilities, cleaning, temporary facilities, administrative expenses, and software fees. They may not be visible at first, but without these costs, the project will not run smoothly.

Allowances or Contingencies

In construction, everything can change every minute. When discussing the design and scope of the project, a risk buffer is included in the estimate. For example, it can be a contingency, a predetermined amount to cover potential risks. Another option is allowances, a budget allocated at the beginning of a project for items with variable costs.

Recommended reading:

Markups

In construction, this is the percentage added to your project’s direct costs to cover overhead, indirect costs, and profit. Overhead includes everything from office rent and insurance to software subscriptions.

Not every proposal based on the estimate will include allowances, contingencies, or markups. This often depends on the project scope, contract type, and the agreement between the contractor and the client.

Types of Construction Estimates

The American Society of Professional Estimators defines five types of estimates. Each serves a specific stage of the project.

Order of Magnitude Estimate

This is an early-stage estimate. Its purpose is to give a broad overview of the costs when the project design isn’t yet available. This is a rough calculation largely based on contractor experience and limited project details. It helps decide whether a project should proceed or be postponed.

Schematic or Intermediate Design Estimate

This type of estimate is created when the schematic design is ready, but the detailed design isn’t complete. As compared with the previous type, it includes more factors. For example, this refers to room layouts, basic dimensions, and key system outlines, giving a clearer cost picture.

Design Development Estimate

This one contains more information as it’s created once the initial design is ready and the scope is well-defined. Contractors can include specific materials, labor requirements, and potential changes. This estimate requires deeper analysis to improve accuracy.

Construction Document Estimate

This type delivers a near-final cost calculation based on final blueprints and technical drawings. There are already exact dimensions, specifications, and construction details. At this stage, contractors can make confident budget and scheduling decisions.

Bid Estimate

The most precise estimate is that prepared right before submitting a bid. It includes all previous data, final documents, and also bid requests to produce a detailed breakdown. Owners rely on this to compare bids and select a contractor.

Step-by-Step Construction Estimating Process

Estimating is a solid process that breaks a complex job into clear steps so you can spot risks early. Each stage builds on the last, turning initial ideas and rough figures into a detailed, reliable cost plan. By moving from reviewing the project scope to applying markups and finalizing numbers, you set the stage for sending a proposal and starting the project.

Project Review and Scope Analysis

Start with the analysis of the project. It is the first step in creating an accurate construction estimate. Initial review involves studying the project drawings, specifications, and requirements in detail.

A general contractor should clarify any unclear points with the homeowner, architect, and engineer. It’s essential to ensure that you fully understand the client’s vision before moving forward with measurements.

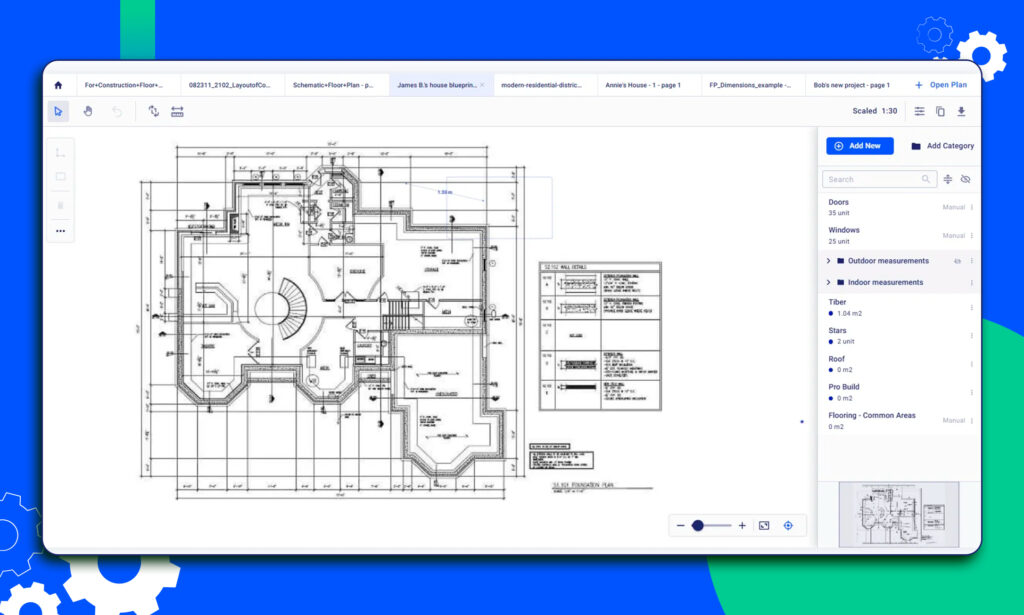

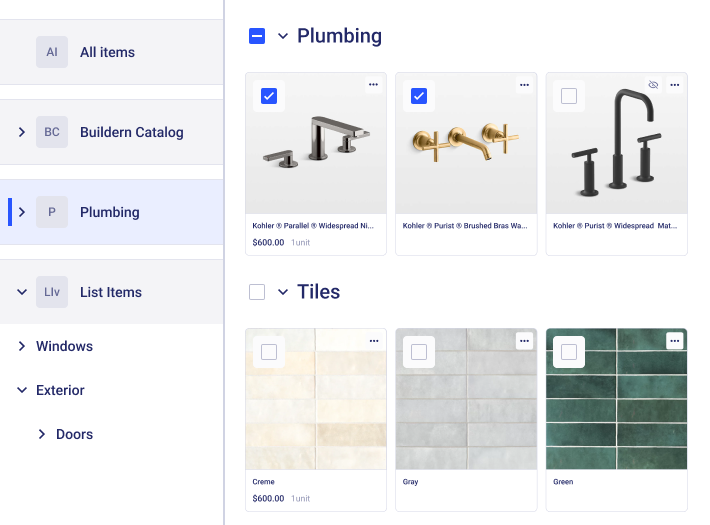

Quantity Takeoff

This is a critical step in construction estimating and is a background for the right calculations. Without accurate quantities, even the best bids can fall apart once construction starts. Takeoff involves measuring and listing all the materials, labor, and equipment needed to complete a project.

A good takeoff process gives your team clear numbers before sending bids, planning, and scheduling confidently. This used to be done manually or with the help of digital tools to speed things up.

In short, quantity takeoff turns an abstract plan into real-world costs. In the case of using construction management software, takeoff can also be based on measurements from existing or new projects you already have. This saves time and resources when creating a new one.

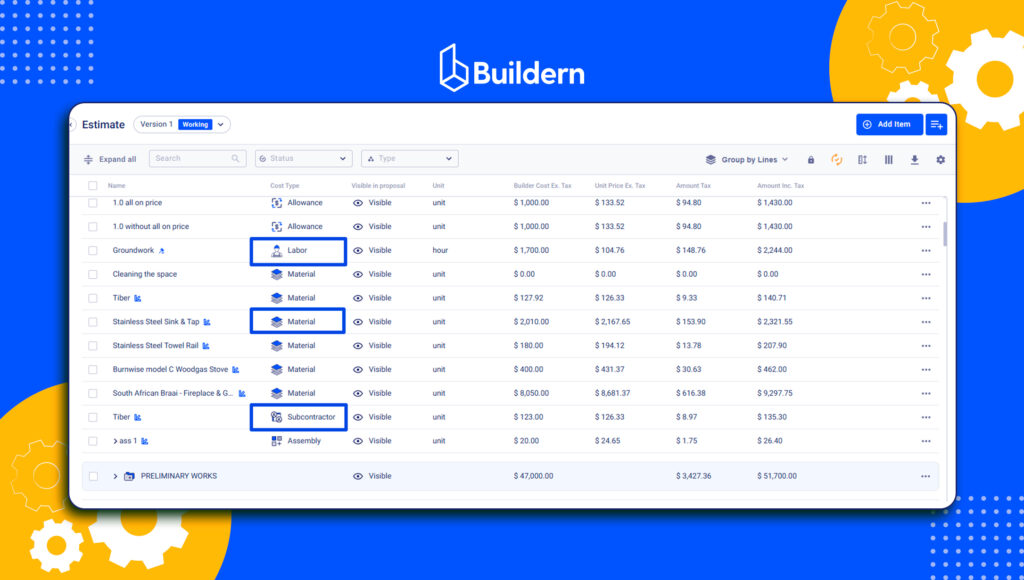

Setting Up an Estimate

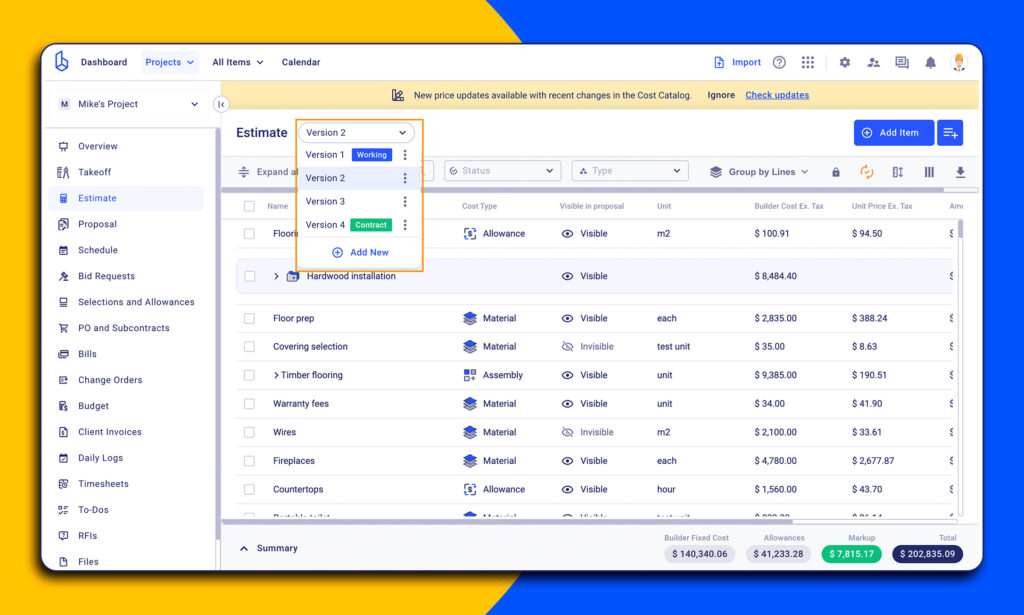

The format of the estimate you choose can vary widely depending on the process and tools. Some contractors prefer doing estimates manually, using spreadsheets. Others rely on specialized construction estimating software that makes the process much easier.

If you’re working manually or with spreadsheets, you might create separate sheets for different parts of the project. It tracks quantities, costs, and labor in organized tabs. This approach offers flexibility, but as the number of projects grows, it becomes more complex.

Digital tools, on the other hand, allow a builder to create multiple versions of an estimate within a single project. Why is it easy? It lets you compare options, adjust quantities, or update prices without starting from scratch. At the same time, you have several internal options, and then decide which one you are going to transform into a proposal.

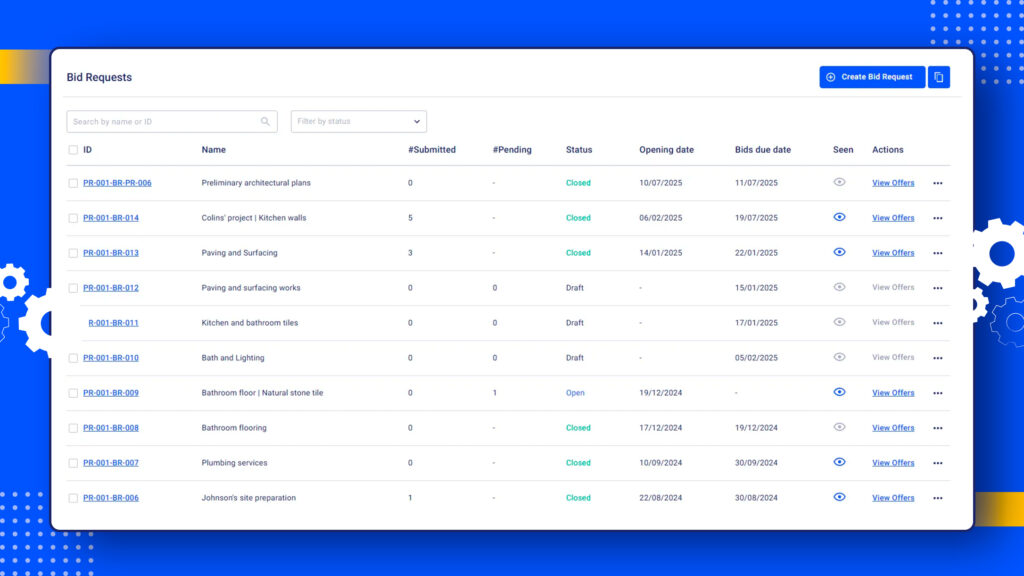

Sending Bid Requests

Accurate estimates depend on real market data. The next step is sending bid requests to subcontractors and vendors for specialized labor, materials, or equipment.

Large projects sometimes require numerous requests and storing data wisely. Each quote can include item descriptions, maximum unit and total prices, visual references, and required files.

Vendors and subs receive the request via email or immediately through the same construction software.

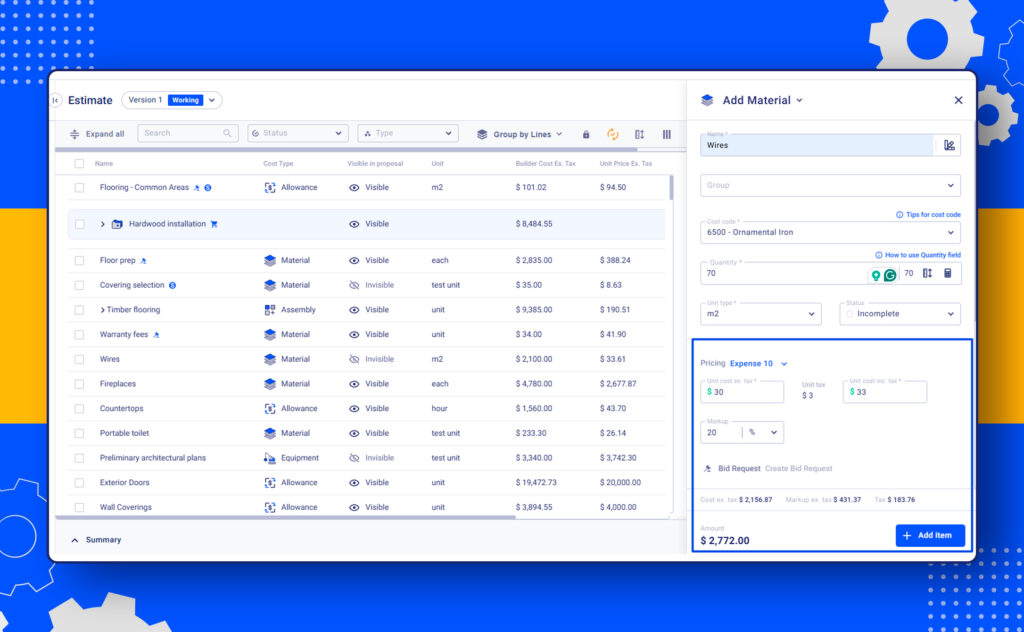

Price Materials, Labor, and Equipment

This is one of the steps that requires attention to detail in the estimating process. A common way to automate this process is to use a construction cost catalog and generate an estimate based on this.

This is a centralized database of current prices for materials, job costs, and equipment costs. Using software, it’s possible to quickly import lists from subcontractors and vendors and create price lists for cost updates.

- For labor, include both hourly rates and required hours for each role to help clients understand exactly where the budget is going.

- For materials, rely on your takeoff measurements and cost catalog entries, but leave room for price fluctuations.

- For equipment, list costs for purchasing, renting, transporting, and maintaining. In many cases, renting, especially for specialized or rarely used machinery, can be far more cost-effective than buying.

The estimate made with digital tools includes all this information and the client can see the price and fee of each item.

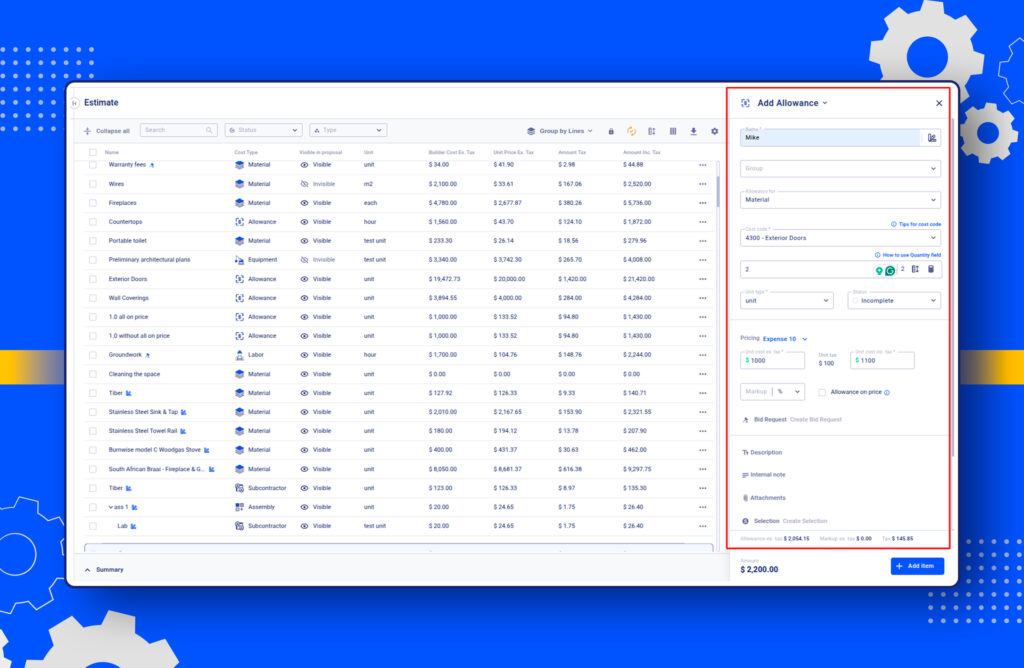

Include Allowances

Allowances in construction calculate the price of items that have not yet been finalized during the planning stage. They give flexibility for design choices or size changes, at the same time keeping the overall budget realistic.

If the exact model of the exterior doors hasn’t been selected, the estimator can assign an allowance. For example, $1,100 for an item based on average market prices. This way, the client can later choose a door within that budget or adjust for a higher or lower option.

Apply Markups

Before turning an estimate into a proposal, the builder adds a markup on top of the direct and indirect costs.

For example, suppose the cost of one meter of electrical wire is $30, you can calculate the total cost plus taxes and apply a 20% markup.

Markups can vary depending on project complexity, market conditions, and risk factors. While some clients may view markups as extra costs, they’re a standard practice.

Finalize Proposal and Submit

After reviewing all calculations, an estimate turns into a professional proposal. Ensure it includes a detailed breakdown of costs, project scope, and timelines.

If using construction software, this can be done via the same platform.

5 Best Practices for Accurate Construction Estimating

The more time and accuracy you invest in preparing an estimate, the smoother your project will move forward. There are some practices you should apply to master this tough task.

- Clear Documentation

Start with clear, complete project documentation so there’s no room for doubt. Every missing detail in the early stages can lead to costly surprises later.

- Cost Updates

Regularly update your cost databases to reflect current market prices, ensuring your numbers stay relevant.

- Involve Key Stakeholders Early

Involve project managers, architects, engineers, subcontractors, and vendors as early as possible. This helps catch potential oversights and ensures all requirements are understood from the start.

- Track Performance After Project

It’s important to track the estimate vs. actual performance after each project. These insights will help refine future calculations and eliminate recurring errors.

- Use Construction Software

All the processes mentioned in a step-by-step guide can become much easier with the estimating software. Buildern, for example, features dozens of functions to automate cost calculations, add taxes, markups, and allowances, send bid requests, and perform other routine tasks.

Who is Responsible for Construction Estimating?

Depending on the building firm’s operations, it can either be a general contractor or a dedicated estimator. Some companies prefer hiring in-house estimators, while others outsource this task.

Why is Estimating Important for a Project’s Success?

This helps keep projects on budget and schedule. Estimates determine project costs upfront. Without them, there is a risk of delays, cost overruns, and profit losses. Accurate estimates prevent financial disasters and allow informed decision-making about scope, labor, and materials.

What Is Construction Estimating Software?

Digital tools can help contractors calculate project costs more accurately and efficiently. The software can be used to automate quantity takeoffs, apply current material and labor rates, and generate detailed cost breakdowns. Popular features include catalog costs, bid labeling, and report generation. This makes the estimating process faster and more precise than manual methods.

Should General Contractors Share Detailed Cost Breakdowns with Clients?

This depends on the general contractor’s business model and relationship with clients. Some contractors provide detailed line items, including the markup, to build trust and justify costs. Others prefer pricing without it to avoid client micromanagement of individual line items.