Construction Rework: Costs, Causes, and Solutions

Imagine completing months of work on a construction project from forming an estimate to hiring subcontractors, only to realize a critical part was done incorrectly. Now, it all has to be redone.

That is construction rework, and it happens with many building firms. Moreover, there are multiple reasons for a rework. However, one thing is common: it damages overall project progress and client relationships. Besides, it may be a signal that something has to be changed in the construction project management.

But what exactly is construction rework? In this blog, we will figure out the real cost of rework, the most common causes, and practical strategies to reduce it.

Table of Contents

- Defining Rework in Construction Projects

- Causes of Rework in Construction

- Cost of Rework in Construction

- How to Eliminate Rework in Construction

Defining Rework in Construction Projects

Construction rework refers to the unnecessary process of redoing an activity that was simply not performed well enough at first.

The rework may include:

- Demolishing and rebuilding completed sections of the building

- Replacing defective materials

- Fixing errors due to miscommunication, inaccurate documentation, or a lack of skilled labor

- Reinstalling systems (e.g., plumbing, electrical) due to design or coordination mistakes

Most importantly, rework is not only frustrating and time-consuming, but expensive. According to industry research, rework contributes to an average of 52% of total cost growth in construction projects and is responsible for schedule overruns of up to 22%.

Causes of Rework in Construction

💡 Let’s break down the common causes of rework and list possible solutions with the use of software.

| Cause of Rework | Description | Recommended Solution |

| Unskilled Labor/Inadequate Training | Workers misinterpret plans and/or do not properly install materials, which often results in poor quality. | Hold regular training sessions and assign tasks based on skill level. |

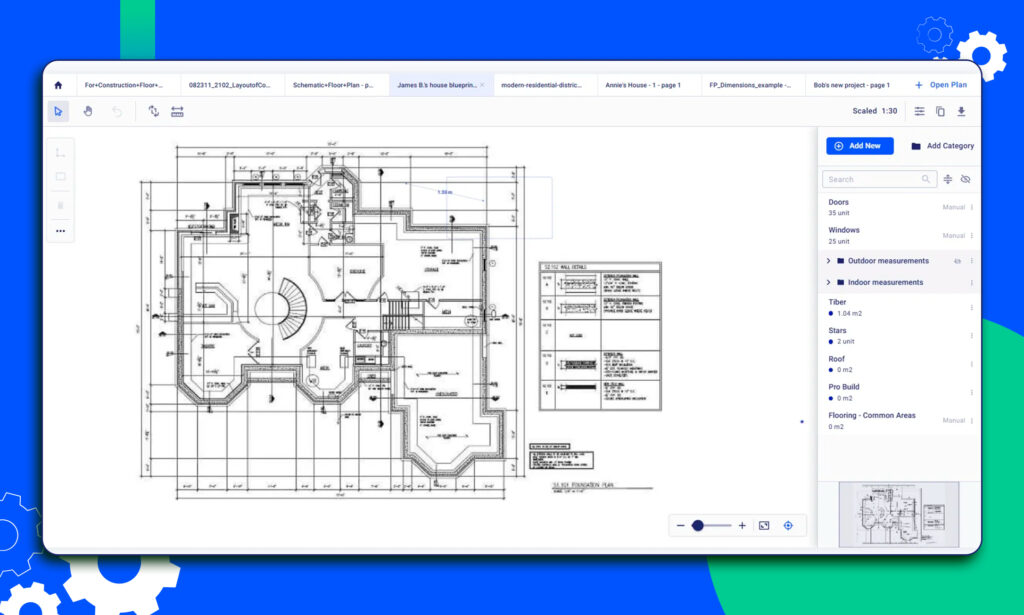

| Poor Quality of Documents | Missing, outdated, or unclear drawings and specifications lead to mistakes. | Use construction software for centralized documentation, including takeoff and estimates. |

| Procurement Errors | Late orders, wrong materials, or improper storage lead to delays or damaged goods. | Automate material ordering and track inventory with construction management software tools. |

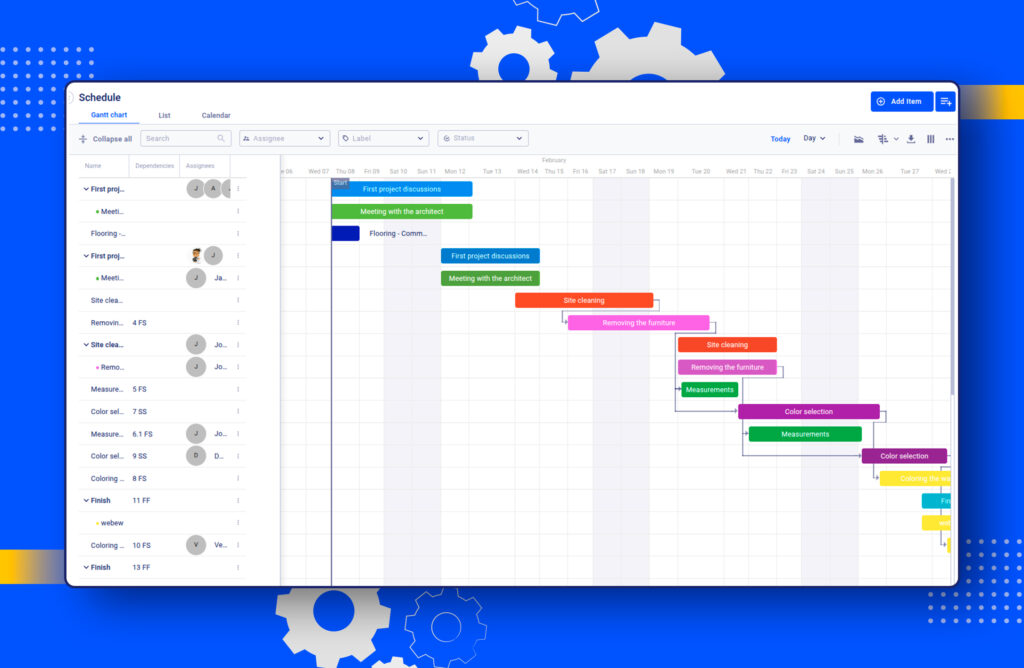

| Unrealistic Project Deadlines | Lack of scheduling and rushed decisions increase the risk of rework. | Create achievable timelines with the dynamic Gantt charts. |

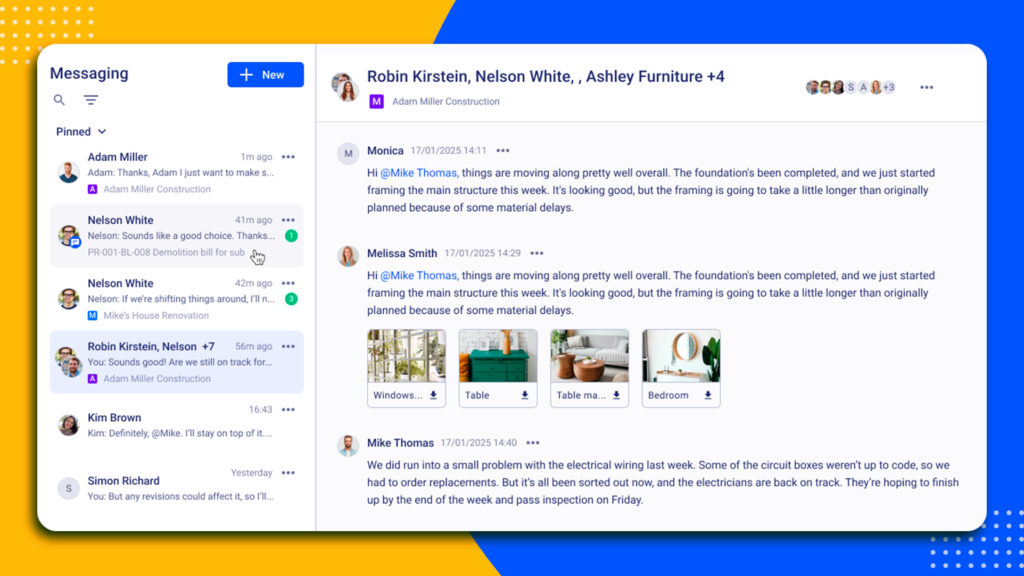

| Communication Breakdowns | Inconsistent or late updates between teams. | Use centralized platforms like Buildern for real-time messages, comments, and task tracking. |

| Lack of Visual Documentation | Without images or videos, it’s hard to verify work and resolve disputes. | Document work with photos/videos and attach them to tasks or milestones digitally. |

Common Rework Issues

Rework is rarely the result of a single mistake. More often, it’s the outcome of a mix of omissions. For example, it can be unclear documentation and/or miscommunication between teams. Understanding what caused the rework is the first step to preventing it.

Unskilled Labor or Lack of Proper Training

In-house teams or subcontractors without the necessary expertise may misinterpret plans or install materials improperly, leading to quality issues.

Incomplete or Poor-Quality Design Documentation

Not having the necessary documents when your construction team needs them is a real problem. However, if the contractor has errors starting from the takeoff, it’s also a problem for the entire team.

As early as the takeoff phase, it’s necessary to have clear calculations. When a builder uses construction management software, it’s easier to ensure that there is correct data from the beginning of a project.

Changes in Project Scope or Client Requirements

Frequent design revisions or last-minute client-driven changes can be a cause of rework, especially if they come after construction has already begun.

Inadequate Procurement

This happens when materials are not purchased on time or when mistakes happen during the procurement process. Additionally, improper storage can also lead to delays, increased costs, and potential rework.

Unrealistic Schedules and Rushed Timelines

Sometimes the deadlines of the project might be way too tight, and as a result, the team might fail to maintain the quality standards.

Poor Supervision

The failure of the management team to oversee the employees and the quality affects the project. The risk of rework increases significantly when a general contractor or a project manager fails to review work regularly.

Communication Issues

If there are communication problems between your teams, it will inevitably lead to misunderstandings. For example, if a project manager updates the schedules but fails to notify a subcontractor.

Cost of Rework in Construction

Overall, rework in construction projects often costs around 5% of the total project cost. The worst part is that the overruns compose approximately 7.1% of overall work hours.

But what exactly are cost overruns in construction? We all know it when we’ve passed our own planned budget. However, when it comes to construction projects, cost overruns might be hard to notice initially.

The reason is that there are multiple teams of subcontractors involved, and many details to consider. A small error in one area can trigger a domino effect.

For example, a subcontractor installs plumbing based on an outdated floor plan. By the time the mistake is discovered, the flooring has already been poured. Now, a general contractor has to replace materials and reschedule labor. A minor mistake but huge consequences.

This scenario shows how rework often leads directly to cost overruns and why careful oversight and documentation are so crucial.

In many cases, overruns come from underestimating actual costs during the construction project planning and budgeting phase. For instance, if material prices rise mid-project, the original estimates quickly become outdated. Add rework into the mix, and it’s easy to see how budgets fall apart.

How to Eliminate Construction Rework

A general contractor can improve the workflow in a way to eliminates rework. It’s clear that unexpected situations are likely to happen. However, with the right working system in place and with the focus on quality from day one, it’s possible to do it.

Let’s focus on the most effective strategies to help your construction team avoid costly mistakes.

Collaborate During the Design Phase

Many rework issues stem from poor or rushed design planning. By engaging with the architect at an early phase, you reduce the likelihood of needing to rework major elements later.

Sometimes, the client wants something that just isn’t possible to build. This may occur due to budget limits, building codes, or engineering restrictions.

For example, a homeowner may ask for floor-to-ceiling windows in a room. However, the architect or an engineer might say the wall is load-bearing. Making that change would require major reinforcement, which means an extra cost.

If these issues aren’t caught early, they can lead to delays or expensive rework once construction starts.

Check Quality

This is done to ensure that the project meets all the requirements and standards of the client. It helps to assure the on-time completion of the project by resolving or avoiding any disputes that might occur in the process.

The quality control checks help to:

- Improve the client’s satisfaction

- Improve the company’s reputation by offering quality projects

- Land more projects in the future

So, try to create a quality control checklist where you would clearly define all the most common problems that might occur during the project. But don’t make it too extensive; try to keep it concise. The shorter your list is, the better you can focus on the critical factors when checking.

After creating a checklist, keep reviewing it and remove the items that always pass the control processes. Instead of them, include the recurring issues that you haven’t thought of in the beginning.

In the quality checklist, you should also be very specific. Remember that you are going to share it with your crew, so they, too, should be able to understand exactly what each item means. Overall, the quality control checklist helps to verify that all the tasks in the project are being completed on time.

Collect Visual Evidence

To protect your work and prevent unnecessary rework, document everything. Photos, videos, and notes are your best friends when it comes to client disputes or internal checks.

Here’s how to do it:

Document everything: Try to document all aspects of your construction project, including the site conditions, any issues that arise, and all the deficiencies. This way, in case construction field rework happens, but it’s not your fault, you can prove it to your clients. Whether it’s your fault or someone else’s, keeping documentation will help you solve the issues faster.

Attach files: If you show your clients that your work was done on time and correctly, this will avoid rework. Some clients might be picky. Unless a builder shows the materials or quality of work throughout the project, they might refuse to pay on time unless specific tasks are redone.

Improve the Communication of Teams

Since miscommunication is one of the leading causes of construction rework, the best way is to optimize the communication channel.

There can be a gap between office and in-field teams. So, it’s essential to avoid problems with order changes, unclear material management, or missing access to some files.

To avoid such issues, clear field-to-office communication is essential. For instance, Buildern’s integrated messaging and documentation tools enable teams to communicate in real time and track updates.

Instead of verbal instructions and field notes sent via different messaging apps, a team gets a single source of files and tasks.

There is also a smaller chance of having things mixed with the client. All messages, approvals, and updates are stored in one place. Homeowners can easily review and approve bids, change orders, or other key decisions.

Monitor Progress and Resolve Issues Early

A big part of preventing rework is identifying small problems before they escalate. Once you have set all the criteria and started documenting the process, it will also be easier to identify issues.

The earlier you solve a problem, the easier it is to keep your project on track. Leaving small issues unresolved leads to a mountain of rework no one wants to deal with.

Implement Digital Solutions

If you’re nostalgic about the “old way” of doing things, this will hardly work efficiently. General contractors’ “tools” traditionally were calls, emails, and spreadsheets. However, many parts of the project management were at risk.

Software platforms should not only replace Excel files. They should work smarter to prevent mistakes. Automation and real-time insights are the best solutions in this case.

With automation tools, you can set up smart reminders for tasks, approvals, or material orders. Moreover, it can also provide real-time visibility into your project’s progress, for example, through Gantt charts.

It’s a task dependency setting to link construction activities like framing or painting in the correct sequence. This alone can prevent many common errors leading to rework.

What is considered rework in construction?

This refers to any activity that must be corrected because it was done wrong the first time. The work is related to all phases of the construction project. It includes fixing design errors, replacing faulty installations, or undoing work caused by miscommunication or poor planning.

What are the most common causes of rework?

Although there are multiple causes, one of the worst scenarios is poor communication. It often leads to budgeting mistakes, scheduling conflicts, and a cascade of other costly errors.

How can automation tools help reduce rework?

They minimize rework as they reduce possible human error and streamline repetitive tasks. If a general contractor has real-time updates and notifications, it helps to learn what’s happening on-site and what’s expected next.

When is the best time to address potential rework issues?

The design and planning phase is the best time to detect possible drawbacks and prevent rework. Once you reach the halfway point of the project, it’s more difficult to correct the mistakes.