What Is a Submittal in Construction: Turn Approval Chaos into Smooth Workflow

On a busy commercial job, there’s no shortage of moving parts and different stakeholders.

Designers sketch, architects revise, while contractors and subcontractors build. Each team has its own set of drawings, specs, and deadlines. When communication is not smooth, it doesn’t take long for a small misunderstanding to lead to some serious mistakes. A single missed detail can ruin schedules, budgets, and most importantly, client trust.

That might be the reason documentation and communication keep everyone aligned and the project running. Every detail has to be reviewed and approved. That process runs through submittals.

In my blog, I will discuss what a submittal in construction is and how they make the approval process smoother and faster.

Table of Contents

- Submittal in Construction Explained

- Common Types of Submittal

- Construction Submittal Process: Step by Step

- Key Documents and Details for Submittals

- Turning Submittals from a Headache into a Workflow

- Submittals: Documents that Prevent Disasters

Submittal in Construction Explained

A submittal is basically a package of information that is used to confirm every piece of work matches the original design. By saying information, I mean everything from drawings and material samples to equipment specifications.

It’s a tool helping teams make sure the right products are ordered and the correct methods are used during a construction project. Submittals are often used in commercial projects since it’s a complex system to simplify the approval process.

In such projects, multiple trades and many participants are involved in the construction projects.

Thus, construction submittals serve as a communication tool or a bridge between the subcontractor working in the field and a designer or architect. The goal is simple: to catch small details before they turn into a big problem. For me, as a project manager, it’s a behind-the-scenes tool that quietly keeps a project running smoothly.

Common Types of Submittals

Information can come in different forms. A drawing, a mockup, or the engineer’s calculations is a submittal with one common purpose: to review necessary parameters and have them aligned throughout the project.

If you understand the different types helps teams coordinate efficiently and prevents errors before they reach the site.

1. Shop Drawings

The submittals are detailed illustrations created by contractors to show how a specific component will be installed.

For example, steel beams or custom cabinetry require precise measurements and layouts. By reviewing them, the design team can verify that the installation matches the original design.

2. Product Data

Documents showing technical specifications and characteristics fall under this category. Manufacturer specifications, brochures, or cut sheets for materials and equipment are types of submittals. When an electrical subcontractor might submit lighting fixture specs, or a plumbing team may provide data sheets for valves.

3. Samples

Physical or digital samples of materials, finishes, or components are also sent for review by the design team. For instance, there are paint colors, flooring, ducts, and fabric samples. They allow the architect and client to confirm the appearance and quality before bulk materials are ordered and installed.

4. Mock-ups

Mock-ups are full-scale, on-site examples of a portion of the project. These are typically used for complex systems such as curtain walls, façades, plumbing assemblies, or even bathroom layouts. In other words, it’s a real part of the project showing how it will work in real life.

For example, before installing an entire glass façade of a big commercial building, a subcontractor may build a small section of it as a mock-up. The goal is to test how it performs under real conditions.

Moreover, engineers are able to check the air leakage, water resistance, and overall appearance and give their feedback to the subcontractor before a massive facade is installed.

5. Manuals and Warranties

These documents are typically submitted toward the end of a project. They provide detailed guidance on how to operate and maintain equipment or installed systems.

Maintenance schedules and troubleshooting of the HVAC unit, along with warranty outlining, come as such documents. They help building owners properly operate the equipment once the building is in operation.

Reviewing them during the submittal process enables the designers and engineers to confirm that all products meet the project’s performance standards and specifications. Let me show how this process works step by step.

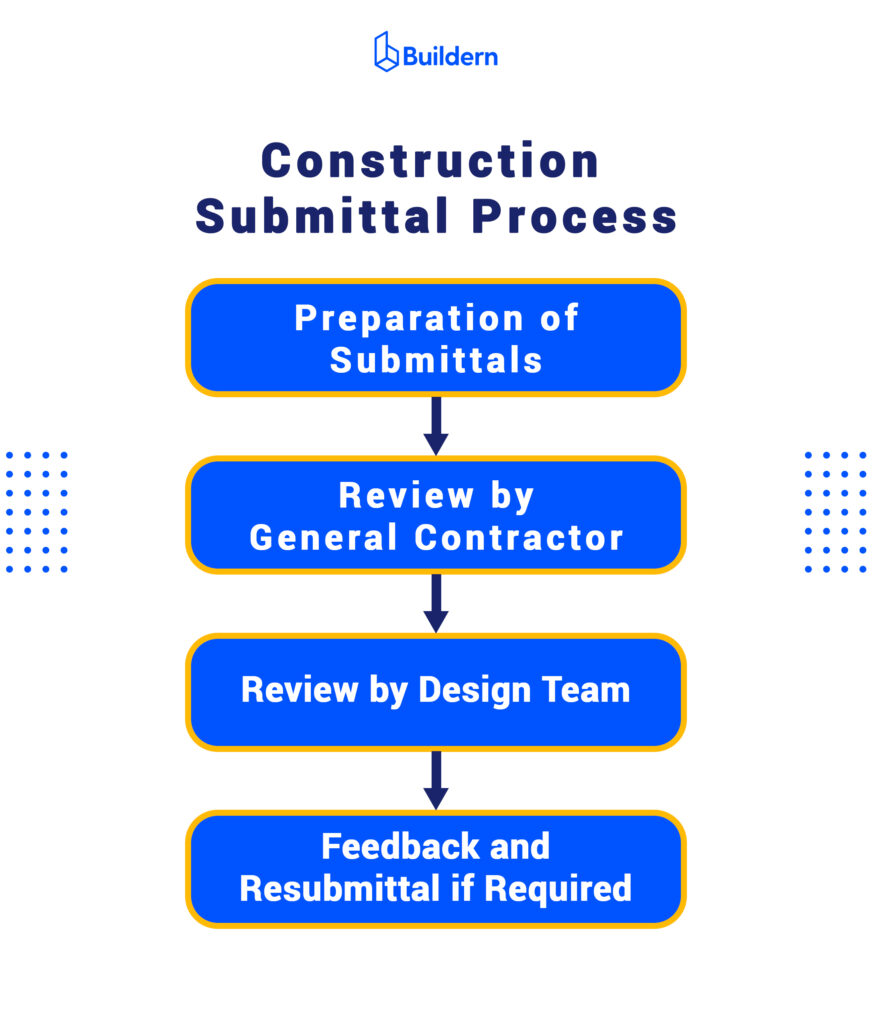

Construction Submittal Process: Step by Step

In a large project, this process is regulated by the contract. There can be a schedule and a detailed process that the parties agree on.

Managing submittals may seem like simple paperwork. However, it’s a clear approval process that starts from the preparation of documents, approval by different teams, including an optional approval from the owner.

1. Preparation by the Subcontractor

The process begins in the field. Imagine I am a subcontractor, for example, an HVAC installer. First, I prepare the submittal package related to the systems to be installed. It can include drawings, manufacturer data sheets, or samples of pipes and fixtures.

What’s more? They can mention the model they use. It’s important to provide as detailed a report as possible to leave no room for further questions.

2. Review by the General Contractor (GC)

A general contractor is the next to review the request. It resembles the first quality checkpoint. The contractor assesses the submittal to check it for accuracy and compliance with project specifications. If any detail is missing, the GC is free to send it back to me for revisions.

For instance, if the HVAC system’s dimensions don’t match the approved drawings, correction is required before moving forward.

3. Submitting Files to the Design Team

Once the document is approved by a contractor, it moves to the design team. The latter may contain an engineer, a designer, or an architect. They check every detail to ensure it complies with the standards and system compatibility. The architect has to review and approve the package.

On some projects, the owner, or a representative, also reviews the submittals, for example, for high-value or specialized equipment. Their approval is the final green light before procurement and installation begin.

What to do After Approval or Rejection?

Once a submittal has been assessed, the next steps depend on whether it’s approved or rejected. If approved, the contractor proceeds with materials and starts work.

For example, if the HVAC subcontractor’s specifications for ducts and equipment match the design, they can begin procurement with confidence that it meets the project standards.

Naturally, there are some cases when submittals are rejected and require revisions or resubmittal. If my HVAC plan shows pipes that don’t match the specified materials or sizes, the GC or someone from the design team will request corrections. My next task is to update the data, make it consistent with the drawings and specifications, and send it for approval.

Keep in mind that submittals can cover a single component, like pipe type, or a larger system, like an entire HVAC layout. It’s also important to have a system where the approval of submittals is simple and does not cause confusion, as it’s a several-step process. It’s a kind of safety barrier that is to ensure quality and catch mistakes before they have a huge impact on the project.

Key Documents and Details for Submittals

The primary goal of every construction submittal is clarity and ensuring that all parties involved in complex construction projects are aware of what to do. Thus, a well-prepared submittal ensures every detail matches the design before the person responsible for procurement or a field team starts installing.

By the way, some organizations and standards bodies publish sample submittal templates to guide contractors, designers, and subcontractors.

Each submittal package typically includes essential project information like:

- Product data, including project name and package number, if it is a part of a larger package, specifications, model number, and technical information.

- Submittal and revision numbers for tracking different versions

- Manager (usually the GC’s project manager)

- Submission and received dates

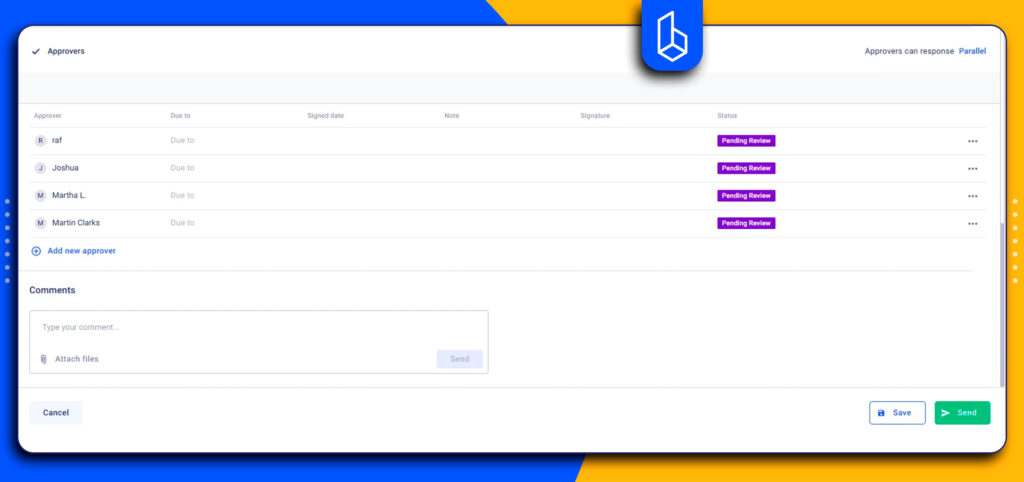

- Approvers (architects, engineers, clients)

- Response status (Pending Approval, Pending Review, Approved, Approved as Noted, Revise, Resubmit, Rejected, or Closed)

- Notes or remarks for comments or revision

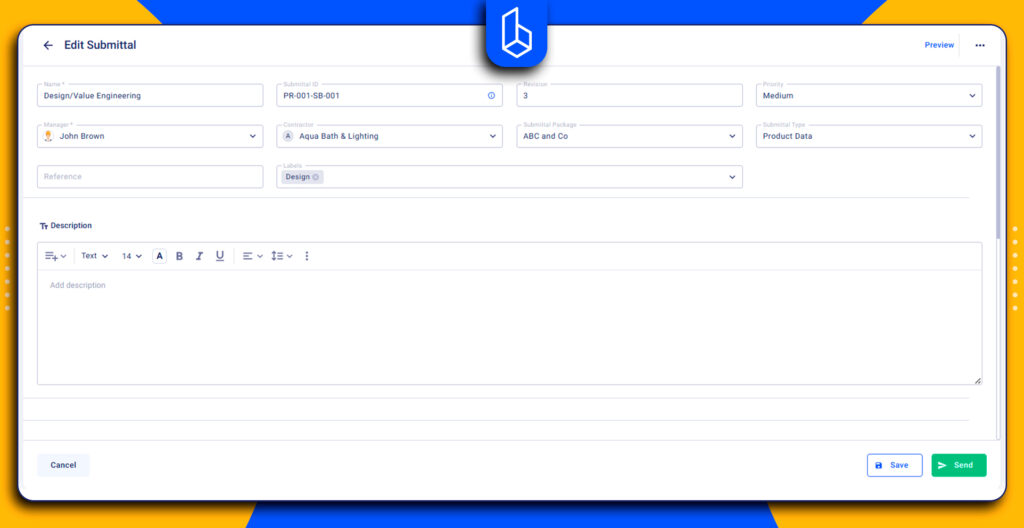

Those are the essential parts. However, when I use our construction management software, the layout of the digital version submittal looks much more structured and automated.

I can create a submittal that contains the above data and important details, like a relation to a particular area (like a change order, purchase order, or daily log) and a particular item.

So, when a subcontractor uploads an HVAC equipment spec, the GC can instantly send it to the architect and other approvers. The architect can add notes directly in the system, attach reference drawings, and return them to the GC.

In addition to the description field, there is also a comment field to use by one of the approvers and the sender.

In this manner, my communication flow is always clear as no details slip out of this channel.

Top 3 Challenges You May Face While Managing Submittals

Over the years, I’ve noticed one pattern repeat itself on almost every large commercial project: you must have to work out an automated and smooth method of dealing with the submittals.

The process sounds simple on paper: send, review, approve. However, in practice, the smallest gap in a missing document or a comment from any of the approvers can affect the entire timeline.

Unexpected Delays

Delays often start quietly. Maybe a subcontractor forgets to attach a manufacturer’s data sheet or uploads the wrong version of a drawing.

The general contractor spots the issue days later and has to send it back for revision. Yes, it all can happen in real life and on a real project. As a result, a single incorrect HVAC submittal, such as a unit not matching the design’s airflow capacity, can halt this part of a project. When the HVAC installation stops in the middle, many interior works get postponed for an indefinite period of time.

Manual Tracking

Email logs and spreadsheets don’t point to late reviews. By the time a general contractor notices the approval is delayed, materials may already be on order. Every day lost in approvals leads to extra costs and stressed-out field teams trying to catch up.

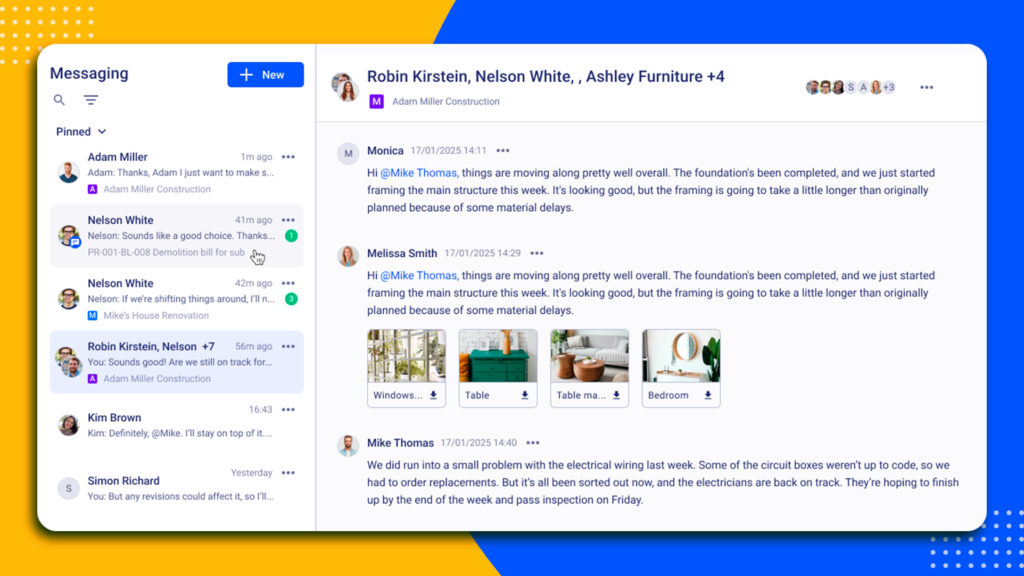

Communication Gap

Then there’s the constant challenge of communication between teams working too far from each other. Architects and field workers often work on different schedules. It’s not uncommon for a project engineer to send a submittal through a project management app, only for a subcontractor in the field to miss the update. When all channels are synced and in one place (no messaging and emails outside the system), one of the key challenges is solved.

How to Turn Submittals from a Headache into a Workflow

Even if I once thought submittals were a headache for me, at some point, you simply find the way to turn them into a predictable workflow.

- The first step is starting early. Planning your submittal schedule at project kickoff gives everyone clarity on deadlines and priorities.

- Next, a standardized template for filling in information. In a digital platform, they follow the same format. Everyone knows exactly where to look for key spec sections, approval or rejection status, and notes.

- Clear communication with stakeholders is critical. Everyone needs to understand how and when approvals will happen. It includes being transparent about any comments or revision requests.

- Reviewing a submittal means having specifications, not just drawings, in focus. Even a beautifully drawn plan can overlook performance criteria or specific product requirements.

- Finally, adopting construction project management tools ensures everyone works in the same ecosystem when it comes to files, comments, and approvals.

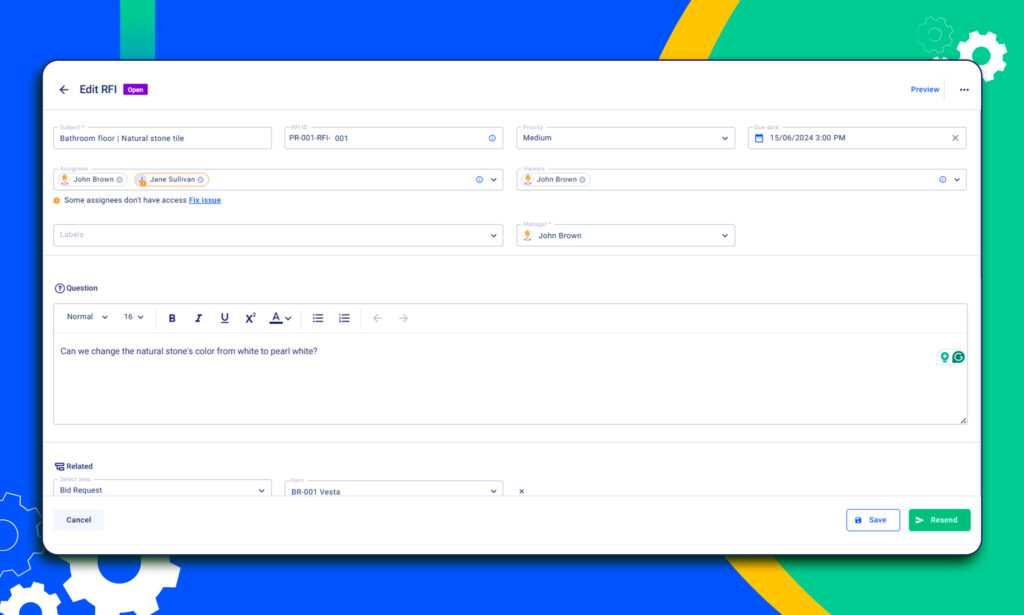

Are Submittals the Same as RFIs?

It’s a common question on construction projects: Are submittals the same as RFIs? The short answer is not exactly, though they’re closely related.

Submittals are requests sent by contractors to architects or engineers for approval before work begins. Their goal is to confirm some points that need to be approved so that they can proceed.

They are especially used in commercial projects as the scope and the number of details are much bigger, and if approval is delayed, the consequences are unpredictable.

RFIs, or Requests for Information, in turn are inquiries sent by contractors when something in the plans or drawings is unclear.

In other words, a submittal says, “Here’s what we plan to do, please confirm it’s correct”. Meanwhile, an RFI says, “We are unsure how this part should be done. Can you clarify?” Both keep projects aligned, but submittals are more about approval, and RFIs are about clarification.

Submittals: Documents That Prevent Disasters

If we want to sum up “what a submittal is in construction,” I can say it’s a safety mechanism preventing a project from failure. They are necessary approvals that ensure every component matches the original design before the work begins.

The main challenge lies in execution. The more automated and structured the process is, the greater the chance of having no problems with workflow. When managed effectively, submittals are no longer an administrative burden but a regular daily task that keeps projects moving forward on schedule.

What is the Purpose of a Submittal in Construction?

The main purpose of a submittal in construction is to get approval from the design team. Getting reviews for the materials, equipment, or a small piece of installation before the major works start. If the design team rejects an item sent for a submittal, the general contractor is responsible for the further changes and corrections to resubmit it.

Can Submittals Be Sent Mid-Project?

Since submitals are often used during complex projects, this can happen frequently. In this case, there are so many different stages and trades involved that a submittal can be prepared before a particular phase starts.

For example, a subcontractor installing electrical systems naturally is not involved from the very start of the project. Thus, they submit the product data or samples after the project starts but before their portion of work begins.

Who Prepares and Reviews Submittals?

Submittals usually start with the subcontractor preparing them. A general contractor is the one to review it first. The next move is to send it to the design team for final approval. In some cases, the project owner also reviews high-value or specialized items.

What to Do if A Submittal is Rejected?

If rejected, a general contractor reviews the feedback and resubmits it for approval.

The contractor reviews a submittal based on the feedback and resubmits it. Work continues until approval is received. This is the reason it’s important to make this process smooth and efficient, as there is a risk of failing the entire project.