10+ Practical Tips on How to Improve Your Construction Efficiency

Every construction team has had a job that looked solid on paper but started falling apart once work began. The materials were late, the trades overlapped, inspections didn’t land on time, and no one could quite explain what happened. Only that the job ran long, and everyone was frustrated by the end.

Construction efficiency is what separates projects that stay on track from those that spiral into delays and cost overruns. It’s how well people, processes, and tools come to keep the work moving.

Table of Contents

- The Current Picture of Construction Efficiency

- Start With Detailed Preconstruction Planning

- Break Projects Down Into Phases and Milestones

- Invest in Skilled Superintendents and Managers, Not Just Labor

- Use Cloud-Based Project Management Software to Centralize Your Workflows

- Standardize Processes Where Possible

- Adopt Modular and Prefabricated Construction Methods

- Improve Job Site Communication With Real-Time Tools

- Plan Equipment Use to Avoid Delays

- Shorten the Feedback Loop Between Field and Office

- Track Key Metrics and Learn From Every Project

- Don’t Skip Daily Huddles

The Current Picture of Construction Efficiency

While overall U.S. construction spending topped $2 trillion in 2024, construction productivity hasn’t kept pace. Labor remains in short supply, with industry groups estimating over 439,000 additional workers needed by the end of 2025.

You don’t need a bigger crew or a new stack of tools to work smarter. What you need is a better handle on how the job runs day to day. This reflects how the best-run teams stay ahead on tight timelines, with fewer delays and less wasted motion.

1. Start With Detailed Preconstruction Planning

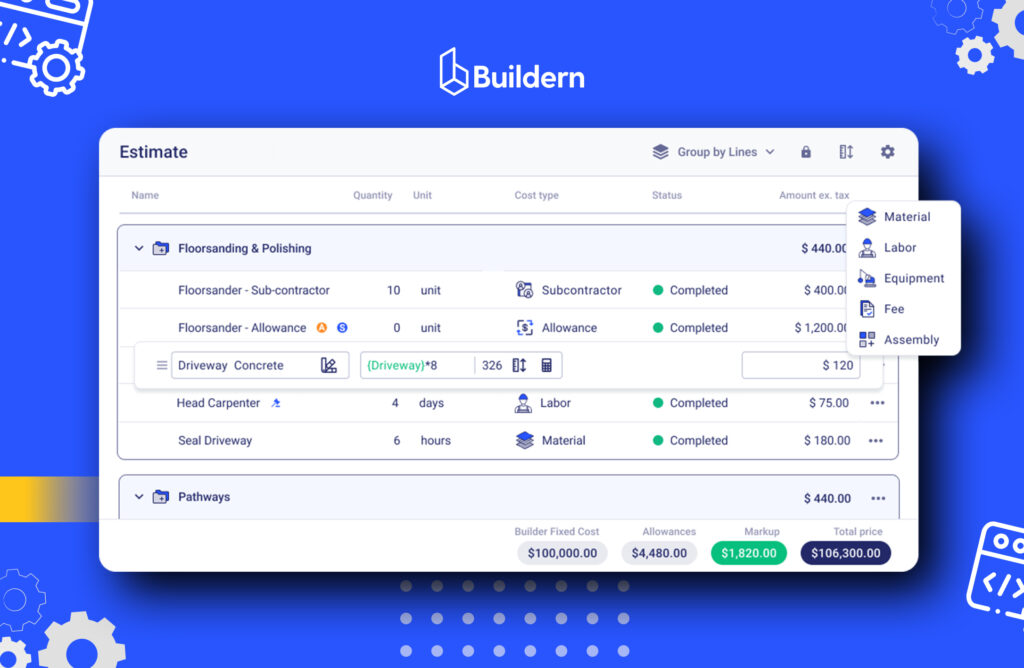

When estimates are linked to job cost categories, scopes, and timelines through a unified platform, the planning phase becomes more reliable. Having labor and materials tied to pre-approved workflows helps ensure project sequencing is accurate before mobilization.

Estimators, general contractors, and other workers reviewing the timeline together with real numbers, not assumptions, can flag problems early and reduce the need for rework.

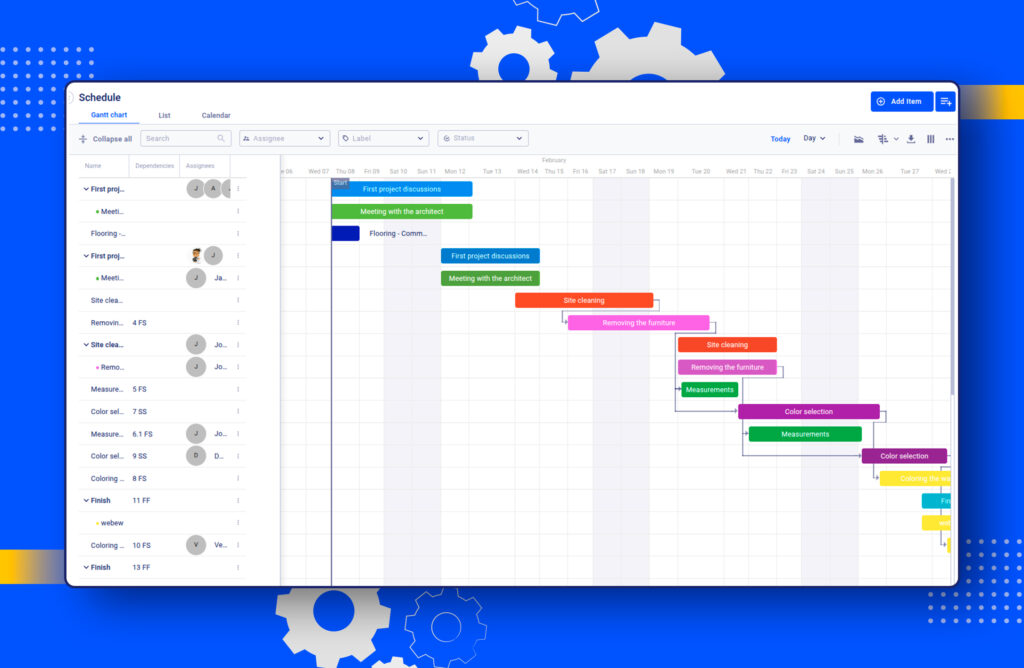

2. Break Projects Down Into Phases and Milestones

It’s easy to lose the thread when everything is running at once. A sudden delivery delay can push a rough-in past its window, and now your close-in gets bumped, and your inspection slot is gone. The bigger the job, the faster small problems start piling up.

Breaking the work into clear, manageable phases lets the team reset before things go sideways. These aren’t theoretical segments. Each phase should be tied to how the work flows. And inside each phase, the crew needs real check-in points for the actual tasks completed.

With activity-based scheduling systems, project phases can be tracked with precise task-level assignments, visible dependencies, and real-time updates from the job site. Each milestone becomes traceable across cost codes, trades, and approval logs. It provides teams with clarity on status and allows managers to adjust schedules early, preventing delays from spreading across phases and ultimately boosting efficiency in construction.

3. Invest in Skilled Superintendents and Managers, Not Just Labor

Crews build the job, but it’s the people guiding them who set the rhythm. A solid superintendent keeps the field moving without pushing. A strong project manager knows when to call the subcontractors and when to call the client before either delays the next step.

It’s easy to assume leadership can be swapped out or spread thin. But the builders who finish on time don’t do that. They know one good superintendent with a tight handle on scheduling, communication, and logistics is worth more than three who are juggling too many jobs or learning as they go.

When superintendents and project managers operate from the same integrated schedule, with access to shared documents, submittals, and progress reports, they’re less likely to miss handoffs or clash over updates. Field-level information feeds directly into the oversight loop, so leadership spends less time tracking people down and more time directing the work in motion.

4. Use Cloud-Based Project Management Software to Centralize Your Workflows

When teams manage projects inside a unified digital environment, documents, schedules, and approvals are visible to everyone who needs them on desktop or mobile.

- Task assignments are centralized.

- RFIs, change orders, and takeoff drawings stay current.

- Updates can be pushed from the office or the field without double entry or email chains.

That kind of shared visibility removes unnecessary lags and keeps the job moving as a unit.

Builders who’ve made the switch to centralized project tools aren’t chasing emails or cross-checking six different spreadsheets. They open one platform, see the status, and act accordingly.

5. Standardize Processes Where Possible

The most efficient projects follow systems. And those don’t have to be complicated. They just require more clarity, consistency, and ease for the teams to apply under pressure.

Standard operating procedures (SOPs) give structure to repetitive tasks that show up on every job, such as:

- Daily logs

- Safety meetings

- Site cleanup

- Toolbox talks

- Change order processing

When these are written down and followed, you spend less time answering the same questions and more time keeping work moving.

When SOPs, safety forms, and inspection checklists are created and stored in a searchable, versioned system accessible on site, crews aren’t left wondering where to find the latest version or who needs to sign off. Progress is documented consistently without having to circle back days later.

Daily reports follow the same rhythm. Supervisors log crew size, weather, inspections, and any disruptions. The report lands in the system before the day ends.

6. Adopt Modular and Prefabricated Construction Methods

One crew is framing while another is unloading drywall. Electricians show up before the space is cleared. Weather closes in, and half a day goes to waste waiting on something that didn’t have to be there in the first place.

Modular and prefabricated methods can help builders avoid such issues. Builders who shift part of the work off-site gain control over sequencing, timing, and quality without trying to solve every problem in the middle of an active jobsite.

The process doesn’t require much effort or additional spending. It can be as simple as rough-in panels that arrive ready to install, bathroom pods built off-site and dropped into place, or custom assemblies framed and wired under controlled conditions. Such pieces show up when they’re needed, go in faster, and reduce job site congestion.

💡There’s also less construction rework.

In a shop setting, the crew works with consistent lighting, fewer interruptions, and better access to tools. They don’t have to adjust for uneven concrete, weather delays, or scheduling collisions with other trades.

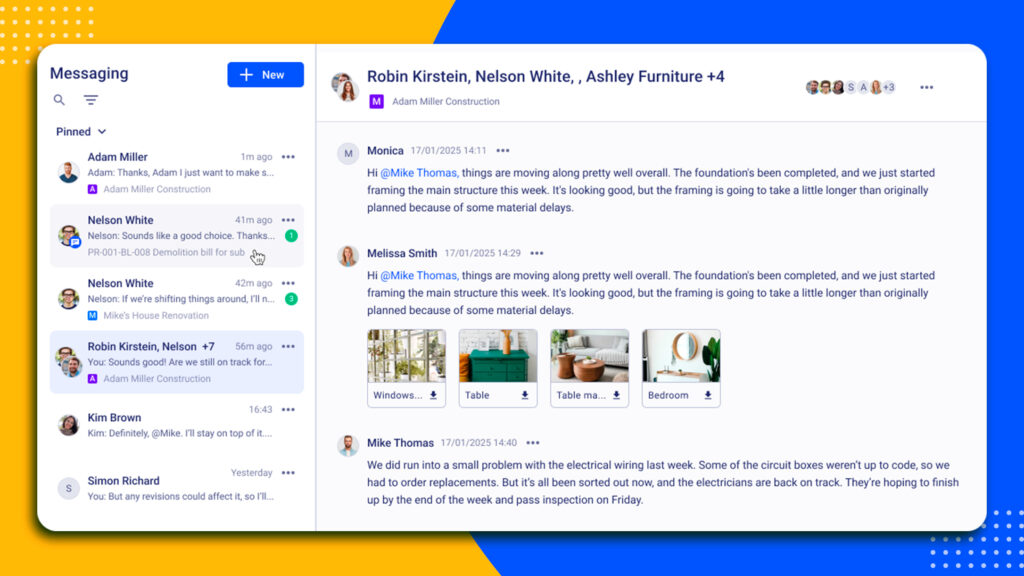

7. Improve Job Site Communication With Real-Time Tools

When updates come late or directions aren’t clear, the work and the whole communication slow down. Builders who keep teams aligned rely on real-time tools that match the pace of the job.

- Mobile applications give crews immediate access to updated drawings and punch items without waiting for someone to print or resend files.

- QR codes placed at key points on the site let teams scan and open the correct plan without second-guessing which version they’re looking at.

- Messaging tools built into the same platform help trades ask questions, document clarifications, and keep tasks moving without callbacks to the trailer.

8. Plan Equipment Use to Avoid Delays

Equipment issues don’t always look like delays until they begin stacking up. When the lift is already tied up, or a delivery blocks access to the concrete pour, trades stand still waiting for something that should have been cleared ahead of time.

Builders who connect resource scheduling to their job timelines and assign visibility by role or trade group can monitor overlaps, prevent conflicts, and adjust plans before fieldwork stalls. A shared calendar showing which crews need what, when it arrives, and how it moves across the site gives the superintendent time to adjust.

This kind of tracking prevents the same problem from showing up twice and keeps trades focused on work, instead of waiting for tools to free up. As a result, construction efficiency grows, and everyone involved in the project is content with its outcomes.

9. Shorten the Feedback Loop Between Field and Office

When issues stay in the field too long without response, they affect the day’s work and shift the timeline. Builders who keep projects on pace remove that lag by closing the gap between where the problem starts and where it’s resolved.

Using software that connects field logs, construction RFIs, and daily progress with the office in real time means the people making decisions don’t hear about the problem days later. A foreman can update progress directly from the job site. The office sees the change, checks what’s impacted, and sends back direction while there’s still time to adjust.

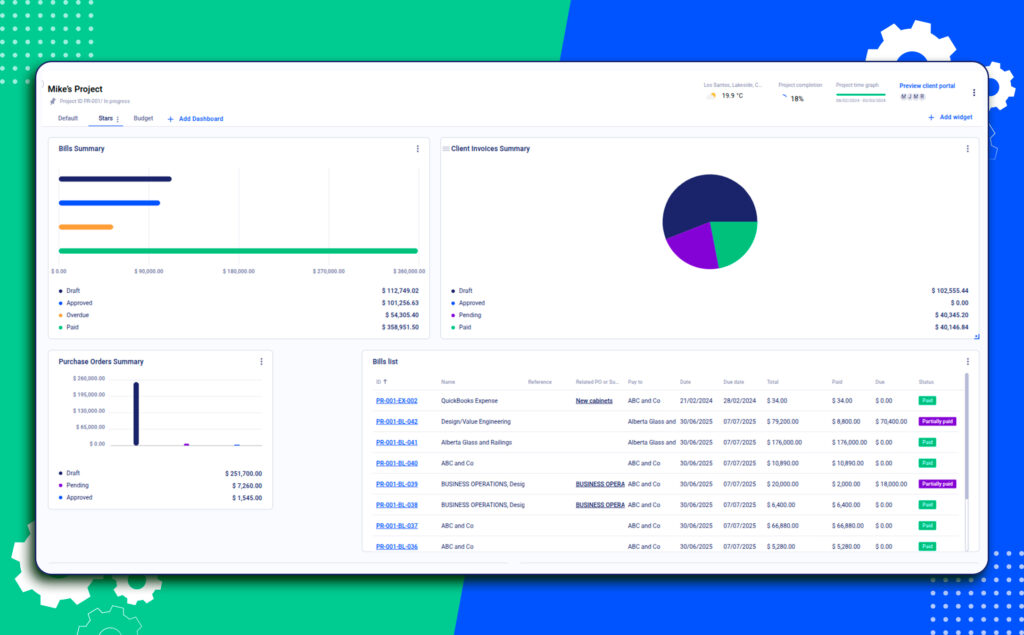

10. Track Key Metrics and Learn From Every Project

Builders who review their jobs with clarity look at project-related and financial metrics that go deeper than budget lines. Labor hours by task, material waste by location, and cost shifts between planned and actual costs each reveal something useful and insightful.

If drywall costs jump every third job, or inspections fall behind by the same profit margin each time, that’s a pattern worth fixing. Builders who collect that data consistently aren’t guessing what went wrong.

11. Don’t Skip Daily Huddles

Crews need short, consistent meetings that remove confusion before it starts. Ten minutes each morning to review what’s expected, who’s working where, and which tasks come first is often enough to keep the day moving without interruption.

These meetings aren’t for reviewing everything, but to ensure the crew walks in with a clear plan. Builders who lead such huddles don’t repeat themselves later. They use the time to confirm alignment, raise safety points, and resolve handoff details that would otherwise show up mid-shift.

How Do You Measure Real Construction Efficiency?

By tracking actual labor per task, rate of rework, inspection delays, and cost drifts, you get a clear performance snapshot and boost construction efficiency levels. Tie these metrics to real-time logs, schedules, and patterns emerge. That may reveal, for example, inefficiencies during framing or recurring misalignments in close‑in phases.

Which Systems Genuinely Move the Job Forward?

Linking schedules, cost lines, RFIs, and daily logs kept and managed all in one place is the first step toward construction efficiency and work productivity. Having access to all the essential data from a phone or tablet right on the job site cuts down on lost hours (sometimes even days) caused by outdated files or confused trades

What Cuts Down on Construction Rework?

Rework is often unavoidable: incomplete drawings, late changes, or mis‑sequenced tasks. Keeping plans, change orders, and approvals tied to job site logs helps ensure the crew works with the correct information. Introduce standard checklists for pre‑task inspection and approvals at every corner (construction QR codes can help with this).