How to Improve Construction Site Efficiency: From Plans to Reality

Every construction project looks efficient on paper. You can have detailed schedules, material lists, and everyone supposedly knows what to do. But once the real work starts, things can go in different directions.

True efficiency is evident in the field, and it becomes clear how well construction teams coordinate, materials arrive on time, and machines operate. That’s when you realize efficiency isn’t about how perfect the plan looks but how smoothly things run in the field

In my blog article, I will discuss what real construction site efficiency looks like. Steak with me to figure out how to achieve it with better planning and team coordination.

Table of Contents

- When to Consider a Construction Site Efficient?

- True Cost of Construction Site Inefficiency

- How to Improve Site Productivity?

- Metrics for Stable Construction Site Efficiency

- Learn from Every Project for Better Efficiency

When to Consider a Construction Site Efficient?

It’s definitely not just when everyone looks busy running here and there or when the schedule seems fine on paper. Real construction efficiency is in the day-to-day rhythm of the job.

As a project manager, I believe the site where I work is efficient when tasks get done on time, within budget, and with minimal waste.

You can usually feel it when you walk onto a site like that. Deliveries show up when they’re supposed to. Equipment runs without constant breakdowns. People communicate clearly, and even when problems come up (they always do), someone jumps in fast to fix them.

This kind of coordination affects profitability, safety, and overall project success. Thus, for me, an efficient site means fewer rework costs, fewer injuries, and happier clients.

It’s no surprise that when people start measuring these things, the numbers back up what we see on the ground. Labor productivity in the United States, for instance, saw a 6.1 percent gain in 2024, following a 5.9 percent rise in output, while hours worked stayed almost flat at -0.1 percent. What that really tells you is that teams are finding ways to get more done without burning extra hours. It’s exactly what a general contractor can expect from the team.

True Cost of Site Inefficiency

Lack of productivity on a construction site creates a domino effect that touches every part of a project. It can happen if subcontractor management is not efficient. People seem to work hard, but no deadline is met, or the quality is so poor that it requires rework. From money to morale, the consequences can be serious if small issues aren’t addressed quickly.

Here are the main ways inefficiency hits a construction site․

Financial Strains

When a construction site isn’t running efficiently, the first place you feel it is in the budget. Wasted materials or mismanaged tasks don’t just add a few dollars here and there but result in considerable budget overruns.

Even if the rework seemed a minor thing in the beginning, it eats into profits, as the time spent fixing mistakes is time when a GC is not billing to the client.

The result is that a general contractor or a project manager starts cutting corners, and the budgeting strategy suffers. Materials ordered at standard rates might need urgent replacements at higher costs, while planned markups can also be affected.

Time Delays

Time is one of the most visible costs of inefficiency on a construction site. In the construction industry, the processes are closely interrelated. Therefore, a late task can hold up another, and suddenly, what should have been a smooth week becomes a mess.

Equipment downtime can halt an entire crew, adding labor costs that weren’t planned. Again, here we have financial risks that depend on efficient construction time management.

No clear deadlines and constant delays stress everyone in the office and on-site. But, for a general contractor, every day lost isn’t just a calendar issue; it’s also a strain on relationships with clients and subcontractors.

Safety Risks from Disorganization

Lack of construction site efficiency highlights how organized a project is. Construction is an industry where site safety must be taken seriously. Scattered tools, materials, and debris can lead to life-threatening injuries.

Moreover, the risks go beyond just physical accidents. Disorganization may cause confusion, miscommunication, and rushed decisions, all of which increase the likelihood of errors. For example, if workers can’t find the right tools or materials, they might use the wrong equipment.

In a large project, small incidents like scattered materials can create dangerous conditions for dozens of people and create obstacles during emergencies. For instance, if evacuation routes are blocked by improperly stored materials or equipment.

Damaged Reputation

In construction, your reputation is your strongest currency. A builder who is known as the one who constantly runs behind schedule and struggles with communication is unlikely to win many projects.

And once word gets out, it’s difficult to cope with the consequences. In the case of a lack of construction site efficiency, clients talk, and subcontractors share experiences. One day, you may find yourself in a position where a vendor will not work with you because of a damaged reputation.

That’s how inefficiency hurts in the long run. Even if the final product meets expectations, the process itself, starting from communication to payment timelines and accurate time tracking, leaves an impression.

Quality Issues

When a site lacks structure and coordination, quality is usually the first thing to suffer. Poor efficiency often means tasks overlap or get repeated as the teams are not working consistently.

Inefficient sites typically suffer from poor information flow. Proper coordination is needed for the tasks not to overlap. If subcontractors aren’t properly coordinated, one trade may unknowingly compromise another’s work.

A client may not be satisfied with the quality of work. Even worse, if the issues are discovered after a handover of a big project, the costs include warranty claims and legal liability.

It’s a shame when a project is ruined not because of a lack of skills, but due to a lack of coordination and organization on the site.

How to Improve Site Productivity?

Construction site efficiency is about working smarter. The goal is to make sure every crew member and material delivery contributes to progress, not chaos.

Here’s how I recommend your team can boost productivity

Streamline Communication

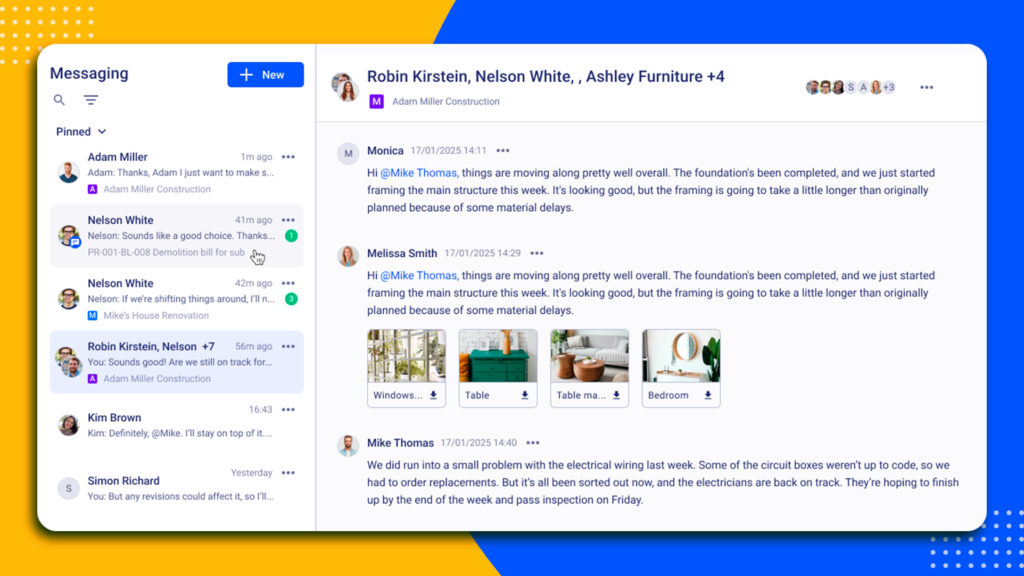

It may sound strange that we talk so much about communication in construction, but that’s where it all starts. Every delay, rework, or safety issue usually traces back to miscommunication, often between the office and in-field crews. When the teams communicate well, problems get solved quickly.

A general contractor can make a big difference by setting up clear communication channels and introducing the right tools. I like to rely on construction management software that keeps everyone on the same page. The goal is to eliminate the confusion of multiple apps, group chats, and scattered updates. With our software, communication becomes an organic part of the workflow.

Do not expect the staff working on the site to be tech-savvy. My pro tip is to apply user-friendly timesheets and QR codes to link files and drawings.

Invest in Workforce Training

A productive crew is continuously learning. If workers know how to use the latest tools, understand updated building codes, or can troubleshoot common issues, they complete tasks faster with fewer mistakes.

Regular training sessions don’t have to be formal events. Sometimes, sharing lessons learned from recent projects is far more efficient. For contractors with in-house teams, this is a long-term investment.

However, for those working mainly with subcontractors, it’s essential to set clear expectations and ensure everyone operates under the same standard. It’s also related to safety training that deserves special attention. The return on investing in training for any aspect of the construction process shows up quickly.

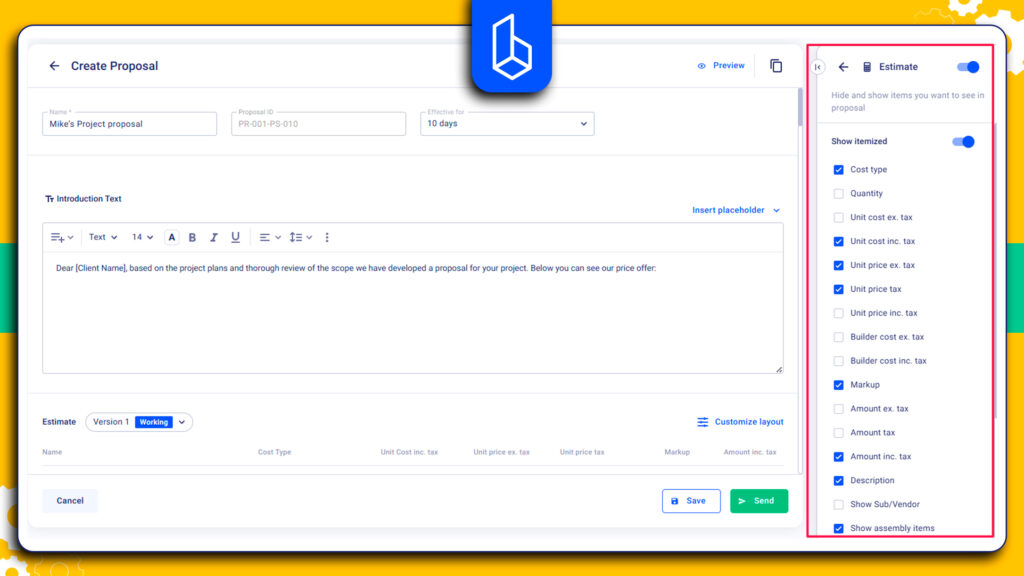

Plan Projects Strategically

A client can understand how efficient you are before the project even starts when receiving a proposal. A clear, realistic plan shows that the contractor understands how to balance costs and the schedule from day one.

The more detailed your proposal is, especially when supported by software that visualizes every aspect, the better it is for your project. For instance, not only are the items and names of works listed, but there are taxes, allowances if needed, and files showing what materials the homeowner can choose.

Ultimately, detailed estimating also helps identify potential risks from material shortages and subcontractor hiring.

If the client sees the budgets that are carefully estimated and timelines are built around real data, he can be more confident in on-site efficiency. Having a plan means the contractor has done the homework, knows the market, and can deliver what is promised.

Optimize Material and Equipment Management

Materials arriving at the wrong time create two equally frustrating problems. Order too early, and the site becomes a storage yard. Order too late, and skilled workers stand around waiting, wasting billable hours

Material management does not work on paper. The solution is matching delivery schedules to actual progress, not just the original timeline. When a contractor can see that framing is running two days behind, they can push back the drywall delivery.

Digital tools make this coordination much simpler. The project manager doesn’t need to walk the site counting material pallets. Meanwhile, subcontractors can confirm their supplies arrived before mobilizing their crews.

The impact shows up immediately in the schedule. Crews work without interruptions, while storage areas stay organized.

Use Digital Documentation

Keeping all project files in one place is a simple but efficient trick. Storing the reports, permits, and schedules digitally when he right information is just a click away eliminates chaos.

No matter if it is a request for information or a submittal, such a workflow reduces mistakes and improves productivity. A subcontractor on-site can check the latest drawings before starting work, and a project manager or a designer can approve changes from the office in real time. Moreover, when signed electronically, it’s not an approved file, but a document.

It’s a simple step that helps spend more time on building, rather than on searching for information.

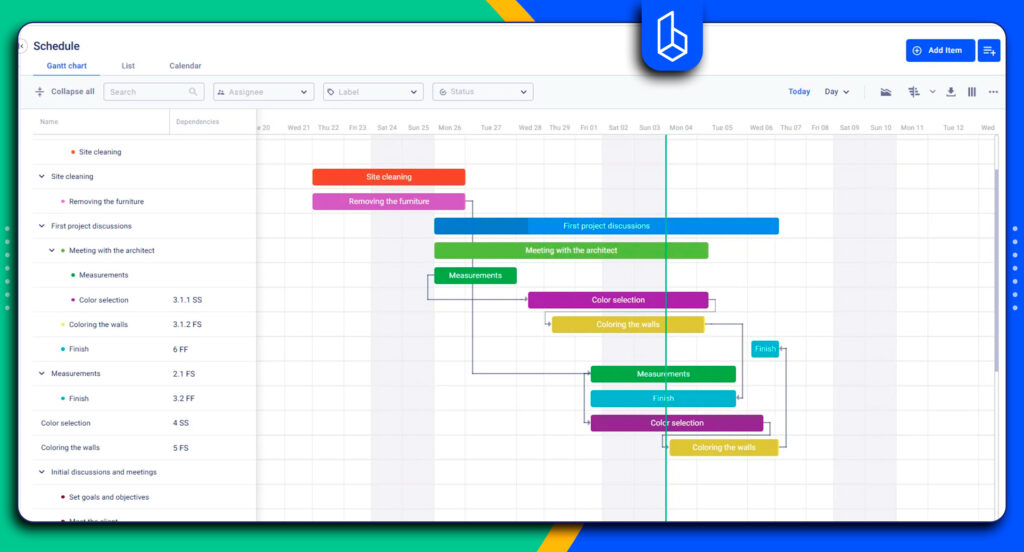

Track Progress in Real Time

The “almost done” phrase usually points to critical problems until it’s too late to fix them efficiently. On a construction site, small delays can accumulate quickly, and that’s why tracking progress in real time is essential.It’s less likely to happen when project managers and crews can see exactly what’s completed, what’s in progress, and what’s behind schedule.

Real-time tracking transforms urgent resolution of problems that resemble “emergency firefighting” into proactive management. The issues are revealed before the inspection steps into the site.

Quick visibility contributes to tighter coordination between trades, fewer weather-out excuses, and reliable planning during various stages.

Metrics for Stable Construction Site Efficiency

| Metrics | What it Measures | Why it Matters |

| Material usage | Waste vs. Planned | Shows how resources are managed |

| Labor productivity | Output per hour | Highlights how well crews use time |

| Project timeline accuracy | Percentage of milestones met on time | Measures planning accuracy |

| Safety incidents | Number per project | Ensures secure and efficient work |

| Rework rate | Percentage of work requiring fixes | Quality of work and coordination of subcontractors |

Learn from Every Project for Better Efficiency

Efficiency is a habit that improves the construction project. It isn’t something you achieve once and forget. Every project, site, and crew offers lessons that can help make the next project more profitable.

I never underestimate the importance of summing up the project. Once it is complete, I take time to review what worked and what didn’t. Were materials delivered on time? Did crews follow the planned schedule? Were communication channels effective? Even small inefficiencies can reveal patterns. If I manage to address them, bigger problems are avoided.

Of course, digital tools make this review process easier. Dashboards and reports from construction management software capture real-time data and allow project managers to analyze productivity. Over time, these insights become a roadmap for continuous improvement.

Efficiency becomes less about luck and more about a deliberate and repeatable process.

What is Site Efficiency?

Site efficiency in construction is when work progresses smoothly without delays, waste, or frustration. If a project is profitable and the client is satisfied, it means you have an efficient workflow. However, consistency is key. A single project going well might be luck or favorable conditions, but when you see the same results across many projects, that’s when you know your systems actually work.

Why is Communication Important for Efficiency?

If communication between the teams and on-site works well, problems get solved before they become expensive. The challenge is that construction involves many people, both in the office and on the construction site. Effective communication means having clear channels where everyone accesses the same information and gets answers to questions quickly.

Is Pre-Construction Important for Efficiency?

Yes, during pre-construction, smart contractors dig into the details. They coordinate work with subcontractors, agree on material supplies, and give clear timelines to clients. If you compare projects, those where pre-construction was rushed will hardly be efficient.