4 Stages of Efficient Construction Procurement Management

Procurement is one of the construction phases that seems simple on the surface. But what I’ve learned from being in the construction business is that there is no easy stage.

Let’s say there is a person who is in charge of ordering tiles. Is it so hard, one may think? The point is that there can be a list of specifications that the tiles have to fit. The order should be agreed on with a general contractor, the subcontractor, and the owner. Moreover, if it’s a commercial contractor, the process is even more complicated.

So planning the materials, lining up the suppliers, and setting delivery dates may seem easy enough in theory. But in fact, procurement as a part of material management is a tough process.

Table of Contents

- What Procurement Covers in Construction

- Key Components of Construction Procurement

- Types of Construction Procurement

- 4 Stages of Procurement Management

- From a Clear Plan to Optimized Delivery

What Procurement Covers in Construction

Procurement is one of those phases that sounds straightforward until you get into the details. It covers many aspects, from hiring subcontractors and selecting vendors to securing materials, equipment, and specialized services.

From my experience, when communication, timing, and document management are synced, the project moves better. When they don’t, even the best crews run by experienced contractors can end up waiting on deliveries that should’ve arrived days ago.

Thus, procurement is essentially about project management. It’s making sure the right materials and equipment are available where and, most importantly, where they’re needed. At the same time, there is no problem with costs and budget.

The responsibility usually falls on the home builder in small projects, like custom home construction. I am the lead when handling everything from sourcing materials to hiring subcontractors. However, on larger projects, there is a bigger team, including project managers and dedicated procurement specialists. Someone tracks deliveries, another negotiates contracts, and someone else keeps an eye on financial management.

Key Components of Construction Procurement

Some may think procurement is the same as purchasing, but they would be wrong. Just going to the store to buy a pack of nails is a purchase. Meanwhile, procurement involves different stages. Here are some responsibilities that are considered a part of this tough job:

Define Project Requirements

It is where real expertise comes in. You can’t just copy and paste a materials list from a past project. Every build is different, starting from the specs to the tools and even the construction management software teams use to manage them.

Send Bids and Select Services

It’s always a temptation to choose the one who offers a price lower than the competitor’s. However, there are high risks of relying on the wrong subcontractor or vendor. It’s about who can deliver quality, communicate effectively, and work within your project’s systems and standards.

As a project manager, I can definitely say a good procurement plan builds relationships, not just contracts.

Buy Materials or Leasing Equipment

While purchasing materials, you have to keep in mind availability, shipping delays, and cost fluctuations. In the case of a larger project, submittals help the project manager of procurement management to verify every detail with the design team.

Monitor Contracts and Schedules

Once everything is underway, it becomes a balancing act. You’re keeping tabs on deliverables, verifying that materials meet specs, and ensuring suppliers do not lag behind schedule.

Manage Conflicts and Risks

From my experience, even the best-planned projects face surprises such as material shortages, design changes, or an increase in prices. A procurement manager is also a negotiator who has to shuffle different tasks, make quick decisions, and renegotiate if needed.

Coordinate Logistics and Material Management

Why is planning important? You need to know exactly when each delivery gets to the site, where it’s stored, and when it’s going to be used. A missed delivery window or misplaced shipment can slow down multiple trades and the entire project. Smooth logistics depend on good planning, constant communication, and often, the right software.

Types of Construction Procurement

Ordering services and purchasing is not a one-size-fits-all process. The way you source materials, equipment, and services depends a lot on project scope, risk, and who’s coordinating what. I will describe some of the most popular procurement types.

Traditional Procurement

Design–bid–build, or also called traditional contracts, is pretty easy at first. The owner hires a design team that finishes the drawings. Once I have a plan, I start bidding to get the most profitable terms. In reality, it’s rarely that smooth as by the time construction starts, even the smallest design change can lead to problems.

Although this method keeps roles clear, changes late in the project can be painful. Coordination here is important as designers, owners, and builders move in sequence, not together. As a result, timelines stretch longer than expected.

Design-Build

Unlike traditional procurement types, this method does not imply having two contracts. One team handles the entire job from drawings to on-site work. A big advantage is that communication flows faster, and decisions are made on the spot.

Unlike bids, the owner invites proposals that don’t just quote a price, as they often include ideas or improvements on the design itself.

Management Contracting

Management contracting takes a slightly different route from traditional methods. Imagine an owner hires a management contractor early on to oversee the entire process from design coordination to subcontractor selection.

Ultimately, the job of such a contractor is to plan, manage, and make sure every trade stays on schedule and within budget. In the same way, a manager undertakes all procurement work.

Construction Management

In this case, the owner gets professional guidance without handing over full control. A construction manager is hired to oversee the project and act on behalf of the owner. However, unlike the previous one, the owner holds the contracts, and the construction manager acts purely as a representative.

4 Stages of Procurement Management

In most cases, the problems during a procurement process do not come at once. If you do not have experience with good coordination, they start small. For example, a shipment was held at the warehouse because of a missing purchase order, or a subcontractor assumed materials were already approved.

To exclude major and minor errors, there should be a clear step-by-step procedure. Let me show how it looks.

Design and Specification

If you ask me, the design and specification phase is where the real groundwork for procurement begins. So it starts with “drawing the plan,” and every detail counts. The owner works with the design team to show the preferences, while the team, featuring architects, engineers, sits down to decide what exactly will be built and how.

One of the key parts of this phase is creating a specification book, a rulebook for materials and workmanship. Contractors and suppliers will later use these specifications to prepare bids and ensure compliance with project standards.

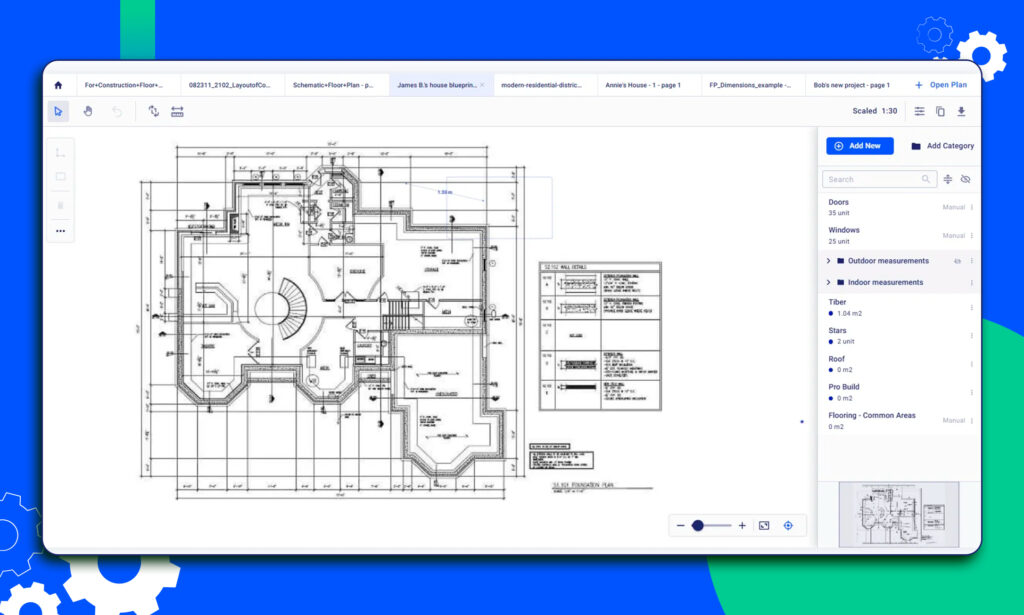

The smallest gap or inconsistency at this phase can turn into costly procurement mistakes later. Here, the digital takeoff is done to provide detailed counts and measurements that help estimate exactly how much material is needed.

In the past, these were done manually with rulers and highlighters. Now, I use our construction management software to make it much easier by letting you organize drawings, link specs with cost codes, and keep every requirement in one place.

Well-structured drawings, takeoffs, and the specification book simplify procurement management. A good digital system also means the design team, contractors, and suppliers are always on the same page. Trust me, that saves countless hours of misunderstanding and minor mistakes once the purchasing starts.

Estimating and Bidding

The next big step is where a builder starts preparing an estimate to sum up all numbers into a clear document. I’ve always found this stage both exciting and nerve-wracking: digging into takeoffs to figure out what the project will actually cost.

It starts with estimating when I break down materials, labor, and equipment needs through detailed takeoffs. It’s like a roadmap for procurement. Knowing exact quantities helps prevent over-ordering or last-minute shortages.

With software, it’s easier to have a structured approach linking estimates directly to vendor databases, cost catalogs, and supplier quotes.

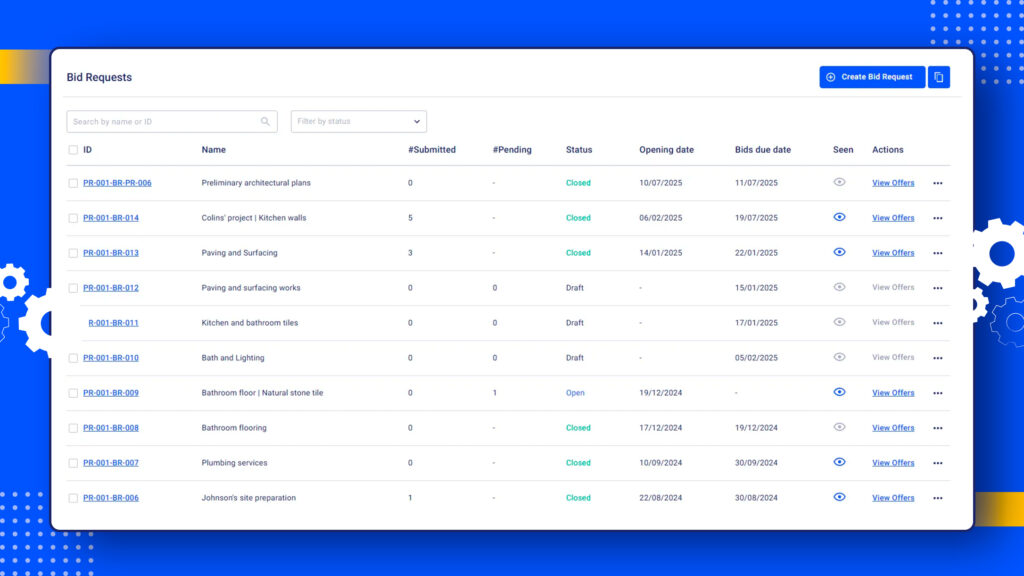

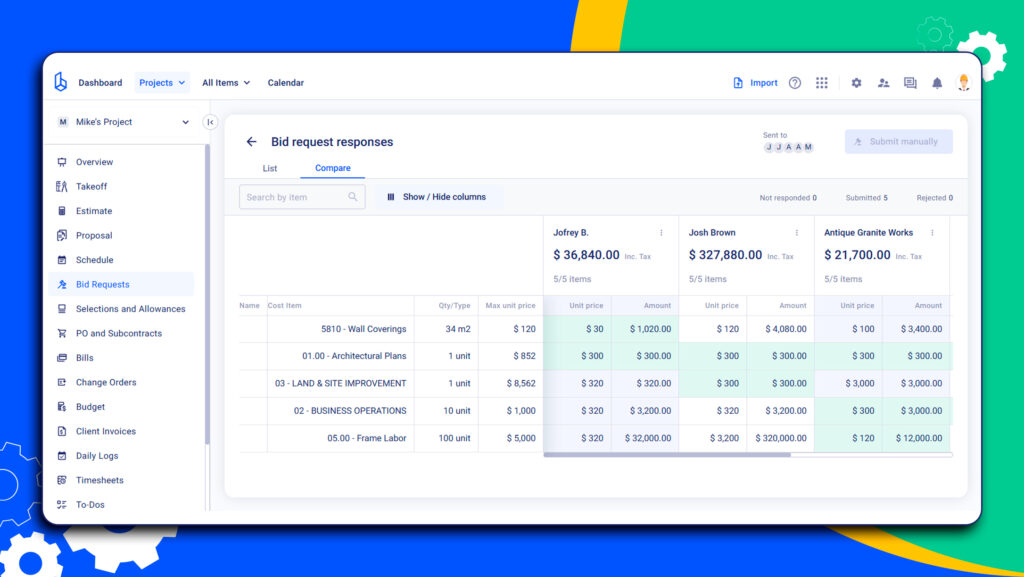

Then comes bidding when subcontractors and vendors submit their prices, timelines, and terms. This back-and-forth can get tricky as materials and timelines or even design details may shift.

Bid leveling when different quotes are being compared is a crucial part for the procurement team or a contractor who is responsible for the entire process. The goal isn’t just to pick the lowest request but to find a reliable partner to have supplies on time and match the project’s quality standards.

The owner then reviews proposals and gives feedback. When the owner makes the final selection and the contracts are signed, procurement officially begins.

However, some projects require multiple rounds of clarification before contracts are finalized.

Submittals and Approvals

At this phase, you have to make sure that what you plan to order is what the project needs. In big projects with hundreds of construction material items and dozens of subcontractors, it’s impossible to proceed to the purchasing phase without approvals.

It starts with gathering submittals. Subcontractors and suppliers submit drawings, product data, or samples for review. The general contractor organizes everything and sends it to the design team. Only when the approval is received, it’s time to start purchasing and further installments.

In this case, especially when done by our software, procurement teams can plan purchases with confidence, knowing exactly what’s clear and what’s still waiting.

Purchasing and Logistics

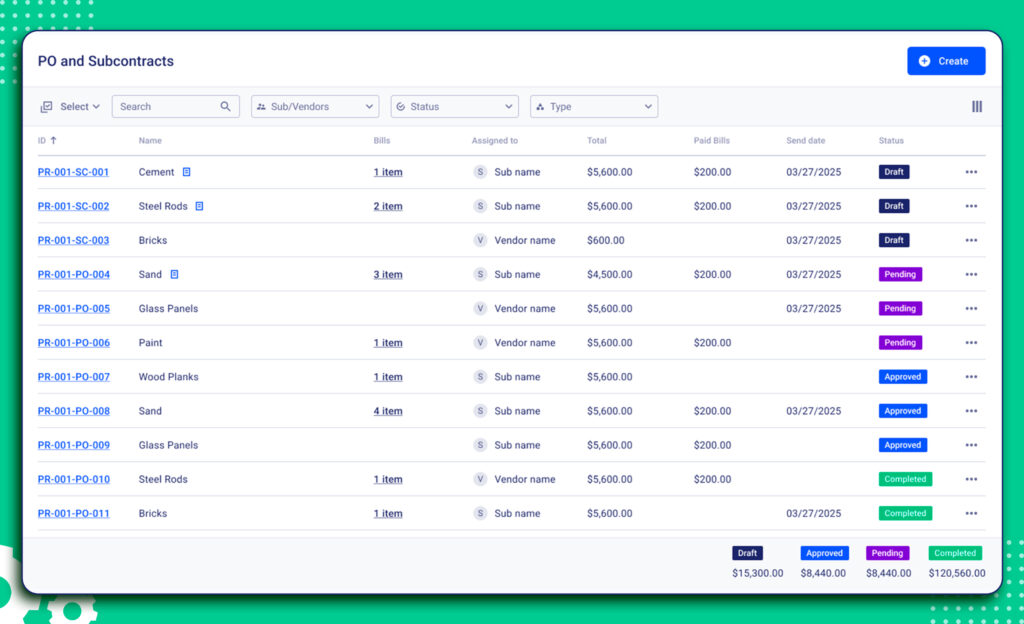

Once the submittals are approved, it’s time to go into action, and procurement becomes real. It begins with creating purchase orders that would include what materials are needed, the quantities, prices, when they should arrive, and how the purchasing process fits other stages of the construction process.

There are different methods of making orders. Naturally, contractors are shifting more to digital POs, which reduce the risk of errors and minimize miscommunication. In the case of hundreds of POs, doing it with software helps track the status of each order in real-time and establish communication with a client and vendor on one portal.

The purchasing process moves into logistics is the next crucial piece when materials should arrive on time and in the right condition.

How to Optimize Procurement Management

The first step in optimizing the procurement process is creating a system that will allow a contractor to have a smooth workflow and not repeat mistakes.

The best way is to start long before anything is purchased. Having clear specifications, detailed takeoffs, and organized submittals makes a difference.

If you’re new to construction, one of the first things to learn is how to set your priorities. What needs to be ordered first? Which materials can wait until midway through the project? Which specialty trades are harder to secure and need to be lined up early?

For example, I always prioritize long-lead items, such as structural steel, custom HVAC units, or specialty equipment, first, while leaving standard materials for a just-in-time approach.

The same is with a database of reliable subcontractors. When using software, the contractor can form a base, a cost catalog with actual prices. Of course, frequent check-ins with suppliers and subcontractors are required to catch delays before they turn into bigger problems.

Finally, it’s about managing risk. Backup suppliers and monitoring price trends help prevent surprises. Optimizing procurement is a multitasking job and switching between communication and using the right systems to keep materials, labor, and schedules all moving together.

From a Clear Plan to Optimized Delivery

Construction procurement is a strategic, multi-stage process that coordinates the entire workflow. It includes hiring subcontractors and selecting vendors to secure materials, equipment, and their delivery.

Successful procurement requires careful planning that starts with detailed design to logistics coordination. Tracking the tasks manually will hardly simplify communication, which is an essential part of procurement. Once great negotiation skills and a structured process turn into a system, not a one-time initiative, the procurement process will be on track.

What Is Procurement in the Construction Industry?

Procurement in construction is not only the process of sourcing, purchasing, and managing all the materials, but also labor and services needed to complete a project. Essentially, procurement connects the design phase to the actual build, ensuring that everything required for construction arrives at the right time and budgeted cost.

What Is the Difference Between Procurement and Purchasing?

Purchasing is a small part of the procurement process and is simply buying materials or services, for example, buying doors. Procurement is a comprehensive process that includes defining requirements, assessing the scope, calculating the quantity of materials, sending bids, selecting vendors and subcontractors, managing contracts, coordinating logistics, and monitoring deliveries. While purchasing is a single transaction, procurement covers the entire cycle.

Who is Responsible for Procurement on a Construction Project?

The scope of tasks differs much on whether it’s a custom home, commercial, or even a larger infrastructure project, such as a bridge or an airport. It can be a general contractor together with a project manager, or an entirely dedicated procurement management team.