Manual Reports Cost You Money: How Smart Builders Use Automated Cost Reporting

Do you ever feel like you spend more time writing reports than actually building? You’re not alone. Manual cost reporting might continue for hours and take too much time.

There are too many small details to include in the work-and-progress report or earned value report. If reporting is delayed or inaccurate, those small details can affect the cash flow and the builder’s reputation.

I figured this out when adding more automation for the cost reporting, which resulted in fewer surprises and systemized reporting. In this blog article, I will break down the essentials of cost reporting in construction: what it includes, how it works, and why it’s crucial for your success.

Table of Contents

- Definition of Cost Reporting in Construction

- Construction Costs to Include

- Types of Reports

- Best Practices for Effective Cost Reporting

- Cost Reporting Process

- Cost Tracking Protects Your Budget and Reputation

Definition of Cost Reporting in Construction

It’s a financial management tool helping a general contractor understand what’s going on with the costs.

Cost reporting tracks every dollar spent, from labor hours and material purchases to equipment rentals and subcontractor fees. Done right, it forecasts costs, gives you insights into where the project is heading, and which tasks are hitting their budget targets.

From my experience, the most effective cost reporting is something you do during the entire project. Real-time updates allow you to make smart decisions. “Are we ordering too much material?” “Is a subcontractor ahead of schedule but over budget?” These are questions a good cost report answers immediately.

Construction Costs to Include

When I review a cost report, I focus on several key categories, each representing a different type of cost. Breaking down costs in this level of detail should be a standard part of any construction financial management.

Direct Costs

These are the costs you can tie directly to the project and its output. They include labour hours on‑site, materials delivered and installed, and equipment used exclusively for that job. Because they’re directly linked, they’re the easiest to attribute and the first place to look when your budget starts shifting.

Indirect Costs

These are the costs that support the project but aren’t tied to a single installation or task. Administrative salaries, insurance, utilities, marketing, and such costs fall under the indirect category. Overhead costs usually make up ~5‑15% of the budget and are essential for running any business.

Contingency Costs

These are unexpected costs that may affect the budget. In other words, it’s a buffer. The unforeseen circumstances may be weather delays, design changes, or supply chain issues.

Fixed vs. Variable Costs

In your cost‑reporting framework, it’s better to separate fixed from variable costs.

Fixed costs are those you pay regardless of output: office rent, full‑time office staff, insurance, or some equipment leases. These costs don’t change much with the volume of work.

Variable costs shift with activity: the more labour hours on site, the more materials you buy, the more fuel your equipment consumes. Variable costs rise and fall with how fast you build.

Cost reporting in construction should highlight both so you can track which one is the troublemaker on this particular job.

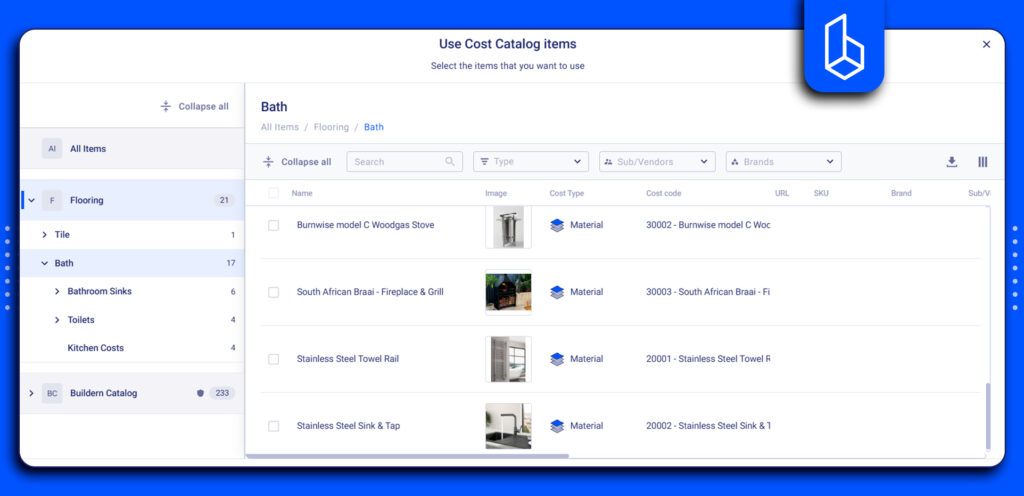

Classification with Cost Catalog

To make cost reporting truly effective, you need a systematic way to classify and organize all these costs. A cost catalog is an easy way to avoid problems connected with manual data entry. A cost catalog is a master database of all your cost items organized into a logical structure. Here are several points that make your reporting easier:

Hierarchy and cost codes: Every item is tied to a cost code (for example, following industry standards like CSI or NAHB). That means when you pull a “labor: plumbing” cost, you know exactly what cost code it falls under.

Item details: Each entry includes descriptions, images, vendor details, unit types, markup percentages, and tax information.

Assemblies and reusable packages: Instead of adding many items one‑by‑one, you create a bundle (for instance, “bathroom installation”) which pulls in all necessary components automatically.

Dynamic updates: When material prices go up or subcontractor rates change, you update the item once in the catalog, and this update is related to all current estimates, budgets, and change orders.

Types of Reports

Not all cost reports serve the same purpose. Depending on what stage my project is in and what I am trying to analyze, each report gives a different angle on financial performance.

Consequently, some show where the money went, others reveal what’s coming next, but together they create a complete financial picture of the construction business.

Let me show the main types of cost reports.

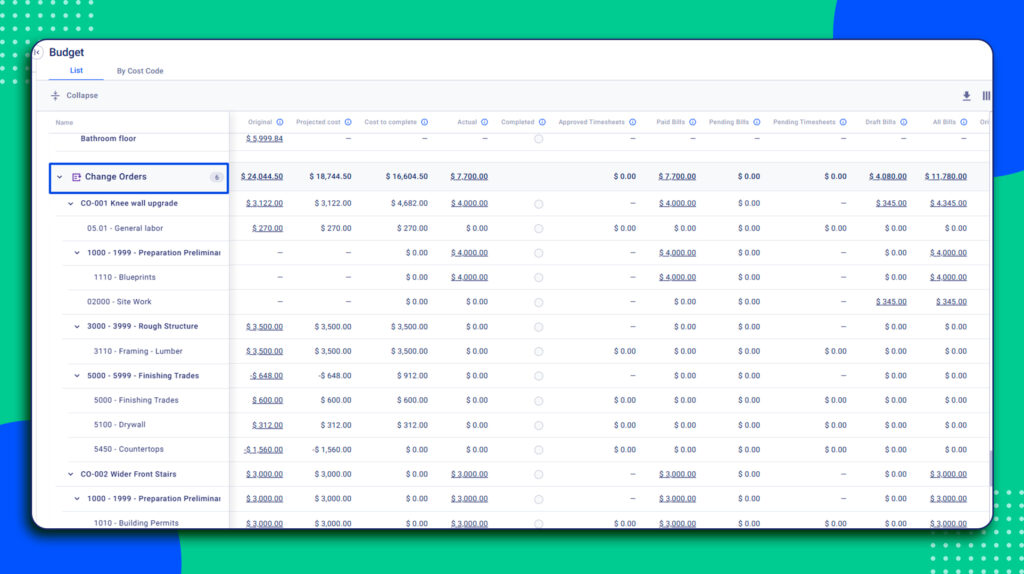

Budget vs. Actual Cost Report

This is the foundation of every cost tracking system. It compares what you planned to spend against what you’ve actually spent so far.

This report highlights variances in real time if labor costs are climbing faster than expected, materials are being used inefficiently, or change orders affect your profit margin.

The power of the report lies in its simplicity. By setting a clear baseline budget at the start, you can continuously measure progress against it as invoices, purchase orders, and timesheets roll in.

Modern construction management software makes it even smoother by pulling data automatically from accounting and field tracking systems.

Cost-to-Complete or Forecast Report

These reports are all about looking ahead. Instead of focusing only on what you’ve already spent, these reports project what the total cost of the project will be once all remaining work is finished.

In other words, they answer the most important financial question every contractor has: “Is everything ok or are we heading straight to cost overrun?”.

The reports combine several pieces of data: actual costs to date, committed costs, and the estimated cost of all remaining tasks. If labor is taking longer than planned or material prices spike, the forecast reveals the impact long before the job reaches the finish line.

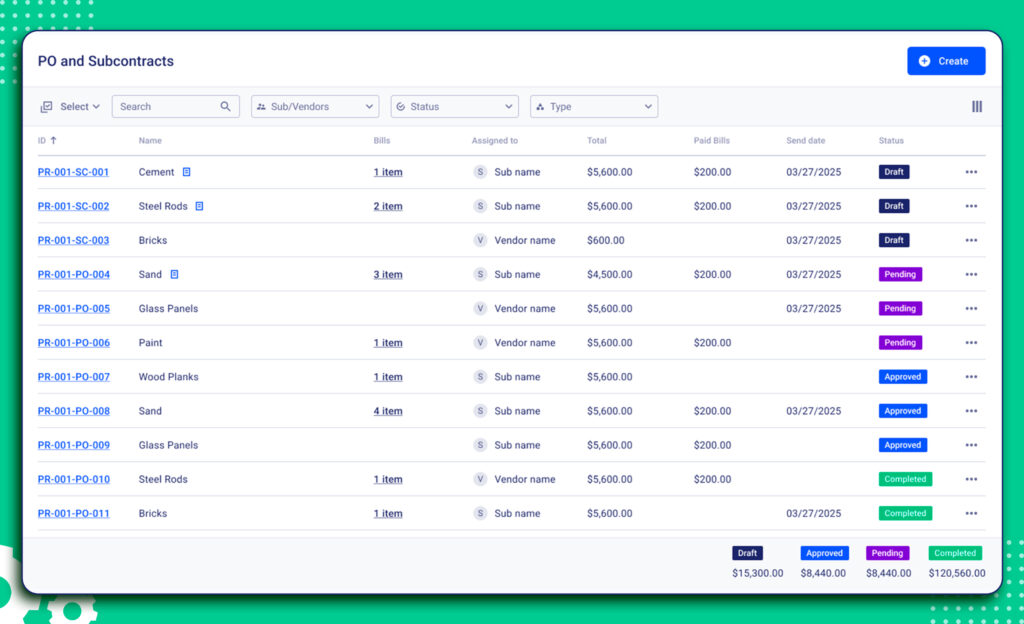

Change Orders

This part of the budget management is one of the most critical components of any construction performance or progress report. They serve as formal documentation of any modification to the project’s original scope. The change orders can involve additional work, material substitutions, design revisions, or schedule adjustments.

Since change orders directly affect cost, timeline, and resource allocation, tracking them accurately is essential for maintaining project control.

A well-prepared report should highlight:

- The number of change orders issued during the reporting period provides transparency into how often the project scope is shifting.

- Reason for each change order (if triggered by design updates, client requests).

- Impact on budget and schedule. Even minor scope changes can influence labor productivity, material costs, or milestone dates.

- Approval status to identify if change orders are pending, approved, or rejected.

In general, too many change orders may seem a bad signal, but construction is a dynamic process. Proactively managing change orders demonstrates strong project management and responsiveness to real-world site conditions.

Earned Value (EV) Report

It measures both cost and schedule performance at the same time, giving project managers a more complete picture of how a project is performing relative to plan.

Those reports are ideal for projects where both cost and schedule are critical. Thus, it works especially during large, complex, or long-duration projects.

The biggest challenge with EV reporting is accurately determining task completion. Reliable methods include physical percent complete (installed quantities), or milestone tracking, units completed (e.g., 10 of 25 doors).

Use EV reporting regularly, weekly, or monthly, to detect trends early, make informed decisions, and communicate performance to stakeholders.

Best Practices for Effective Cost Reporting in Construction

It’s crucial to unders when and how to track costs. I will list some efficient strategies to avoid major problems.

Determine Reporting Schedule

For active projects, I recommend a weekly cost update. This doesn’t have to be a comprehensive report, but rather a snapshot of subcontractor commitments and change orders. Weekly updates allow you to spot trends, address inefficiencies, and communicate issues to the team.

Monthly reports are better suited for management and stakeholders who need a summary of overall project performance. The key is to establish your schedule at the project outset and stick with it, as consistency matters.

Apply Automation in Cost Reporting

Automation saves time and reduces errors, ensuring consistency across projects.

For example, when a change order or a new purchase order is approved, it’s automatically updated in the budget. Besides, construction management software can pull data directly from timesheets and purchase orders.

Use Standardized Cost Codes

Establish a consistent cost code structure across all projects. When every project uses the same codes for “framing labor” or “electrical rough-in”, you can build more accurate estimates based on historical data.

Cost Reporting Process

From my experience, the first step is data collection. Make sure you have as much detailed information as possible from timesheets, invoices, purchase orders, subcontractor bills, and even receipts for small purchases. It’s something that construction management software can ensure.

Don’t just dump numbers into a spreadsheet; assign costs to the right categories in the catalog. It makes your reports meaningful and helps you see where margins are leaking.

Once the data is organized, it’s time for consolidation and analysis. Combine all project costs in one place, check for inconsistencies, and compare against your budget. Finally, establish a review and approval workflow.

Cost Tracking Protects Your Budget and Reputation

Cost reporting is your early warning system for budget issues, inefficiencies, and cash flow problems that can damage the entire project.

The difference between struggling contractors and successful ones often comes down to how they handle financial data. Manual reporting is slower, with more mistakes and challenges. By the time you spot a problem in a spreadsheet, you’ve already lost money.

Meanwhile, automation helps centralize all your financial data in one place. Real-time visibility means real-time control. You can instantly see if labor costs are climbing or if a subcontractor is over budget.

Smart cost reporting combines the right data structure, the right frequency, and the right tools. When cost reporting becomes systematic and automated, you stop reacting to surprises and start controlling outcomes.

What Is a Project Cost Report?

A project cost report is a financial snapshot that tracks all expenses against your budget. It shows what you’ve spent, what’s committed, and what’s left. It gives real-time control over project finances and helps you spot problems on time.

How to Do Cost Reporting in Construction?

Start by collecting all financial data, including timesheets, invoices, purchase orders, and subcontractor bills. Organize costs using standardized cost codes. Use construction management software to automate data collection and generate reports weekly or monthly for consistent tracking.

What Does a Cost Report Include?

A comprehensive cost report includes direct costs such as labor and materials, indirect costs (overhead), committed costs (approved purchase orders), change orders, and contingencies.