Construction Contingency: How Much You Really Need in Your Budget

Budget problems on a job rarely arrive as one big surprise. They usually creep in quietly. A detail in the takeoff plans shifts after a meeting, resulting in changes in your estimates. The team uncovers something on site that nobody could see earlier. I assure you that these moments are normal, but they still affect the numbers. When they all add up, the only thing keeping the budget steady is the construction contingency you built in at the start.

So, my key advice to you is to stop treating contingency as an optional cushion. Simply, view it as a part of making the budget work. A defined contingency gives the project management a bit of breathing room, which is usually all it needs to stay on track.

Table of Contents

- What Is Construction Contingency?

- Why Contingency Is Essential in Every Construction Budget

- Types of Construction Contingency

- How Much Contingency Do You Really Need

- How to Manage and Track Construction Contingency

- How to Communicate Contingencies With Clients and Stakeholders

What Is Construction Contingency?

Simply put, construction contingency is the portion of the budget set aside for the things you cannot fully predict.

It is money reserved for the surprises that appear along the way, even on projects that feel well understood during preconstruction. It is not meant for upgrades or scope changes while playing a different role. Contingency absorbs uncertainty so the team can deal with issues without breaking the whole financial plan.

💡 Here’s a tested tip from my team: a simple explanation helps align the expectations. When everyone knows what contingency is for, the project avoids long discussions later about whether a cost belongs in it. Instead, the team can focus on solving the issue and moving forward.

Contingency vs. Allowances vs. Reserves

There are builders who often use these terms interchangeably, yet they serve different purposes. Projects run smoothly when everything stays separate in the budget.

Contingency covers unknown risks. Not because the team missed something, but because some parts of the work cannot be fully understood until construction starts. For example, unanticipated soil conditions or small structural adjustments during coordination.

Allowances cover items that are part of the scope but not fully chosen or priced yet. A flooring allowance or a lighting allowance fits here.

Management reserves are different. They are usually kept at the organizational or owner level for larger disruptions. These are not pulled into daily site decisions.

When these three categories blur together, it becomes harder to track where the money goes. A project that keeps them separate builds a clearer financial picture and avoids confusion later in the job.

Why Contingency Is Essential in Every Construction Budget

Cost pressure shows up on nearly every job, even when the planning looks solid on paper. None of the unexpected changes should be unusual, yet acknowledging that they still affect the bottom line is important. Construction contingency is the part of the budget that absorbs these hits, so the team doesn’t have to renegotiate every time something moves.

One of the first places you see this is during design development. Early documents rarely stay untouched. Mechanical layouts can be adjusted, and structural notes may require extra clarification. A simple reroute can alter labor or material quantities in a way that wasn’t obvious at bid time.

Then there is the market. Material prices are constantly changing, especially for steel, concrete, or mechanical components. A small swing in a few categories is enough to push the estimate off balance during procurement.

All these adjustments add up. Without contingency, the team is forced to pull money from other parts of the project or reduce quality just to stay within the limit. A well-set contingency prevents that, giving the project the flexibility it needs to absorb normal fluctuations without changing the entire plan.

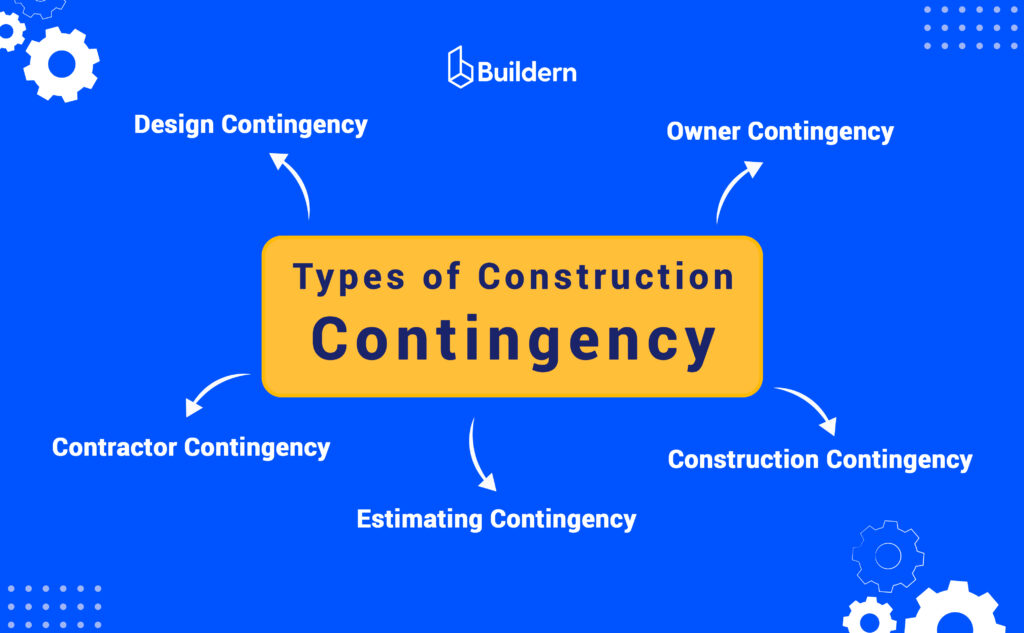

Types of Construction Contingency

Most builders use the phrase “construction contingency” in a general way, but in practice, several different types exist. Each one covers a specific kind of uncertainty.

Breaking them apart will help your team understand which risks belong where, instead of treating everything as one big catch-all.

Design Contingency

Design contingency applies mostly in the early stages of a project. Drawings evolve with each round of coordination, meaning that if a detail looks complete during schematic design, it might still change once the trades start laying out their systems. Electrical clearances, pipe routes, and slab openings all shift as the picture becomes clearer.

The contingency buffer helps handle those refinements before the documents reach a fully buildable stage.

Construction Contingency

Once field work starts, new challenges come into play. Now the risks come from the job site itself. Weather, unforeseen structural conditions, access limitations, or sequencing adjustments might appear as the build progresses.

Construction contingency covers these real-world issues. It gives the team a way to adapt without forcing a budget rewrite every time something on site behaves differently than expected.

Estimating Contingency

Even with good takeoffs and vendor quotes, estimates never capture everything perfectly. Some scopes remain incomplete at bid time, especially on complex projects where not every detail is finalized.

Estimating contingency is the financial pillow for these unknowns. It accounts for the natural limitations of early pricing before the project shifts into procurement.

Owner Contingency

Owner contingency sits on the client’s side. It is usually used for strategic decisions or adjustments that improve the project but were not initially locked in. Maybe the owner wants to upgrade finishes after seeing samples. Maybe they want to expand the program or adjust part of the layout. The owner contingency gives your clients room to make these decisions without disrupting the main budget structure.

Contractor Contingency

Contractor contingency is controlled by the builder. It is the practical working buffer for subcontractor coordination, minor field fixes, or unexpected labor and equipment adjustments. It doesn’t suggest scope changes but rather the normal fluctuations of managing crews and keeping the job moving. A builder who carries their own contingency usually handles these small issues quietly, without escalating every item to the owner.

💡 Useful to Consider…

Owner and contractor contingencies often get mentioned in the same breath, but they serve different roles once construction begins. Keeping them separate helps avoid misunderstandings later, especially when the project takes an unexpected turn.

When both contingencies exist, the project has a clearer structure for handling financial issues. Each side controls its own buffer, preventing pressure from falling entirely on one party when something unexpected comes up. Many teams find that dual contingencies create smoother conversations because the responsibilities are already defined before the work starts.

How Much Contingency Do You Really Need

Every project carries its own mix of uncertainty, so picking a fixed percentage rarely makes sense. I’ve seen how some builders still rely on a default number, but most experienced teams adjust contingency based on the actual risks they see during planning.

A renovation with limited documentation will obviously need a different buffer than a new warehouse on clean, open land. Thinking about contingency this way helps keep the number realistic rather than arbitrary.

The Risk-Based Formula

Instead of choosing a percentage first, I recommend looking at the main risk drivers and building the contingency from there. Several factors have the biggest influence:

- Project size. Large builds carry more activities and more coordination points. With more moving parts, the chance of encountering a cost-impacting issue increases.

- Construction type. Renovations almost always bring greater uncertainty than new construction. Unknown structural conditions and concealed utilities introduce risks that are hard to estimate early.

- Document maturity. The earlier the estimate, the less defined the drawings. Schematic-level documents require a higher buffer compared to a near-final set.

- Geotechnical uncertainty. Soil behavior has a significant impact on both cost and schedule. Limited testing or mixed site conditions push the required contingency higher.

- Contract structure. Lump sum projects place more risk on the builder. GMP or cost-plus jobs distribute the risk differently, which influences how much contingency sits on each side.

- Market volatility. When pricing swings quickly, even a stable estimate can shift during procurement. Materials with long lead times tend to carry the greatest exposure.

Looking at these drivers together gives a more accurate picture of the required buffer. You may even revisit the percentage after major design milestones to keep the contingency aligned with the project’s actual risk level.

Typical Percentage Ranges

Although percentages vary by region and project type, the ranges below reflect what many builders use as a starting point before adjusting based on the factors above.

New Construction

- Low-risk projects: 3-5 percent

- Typical mid-range or moderately complex jobs: 5-8 percent

- High-risk or highly coordinated builds: 8-12 percent

Renovations and Additions

Renovation work introduces more uncertainty, especially in older structures.

- Standard renovation with limited unknowns: 10-20 percent

- Older buildings with concealed conditions or structural unpredictability: up to 25 percent in specific situations

Public Works

Public-sector guidelines are often more standardized.

- Many agencies require 5-10 percent, depending on project scope and documentation quality.

These ranges are not strict rules, but they give the team a practical frame of reference. The real value comes from adjusting them to the actual risks identified during your construction project planning.

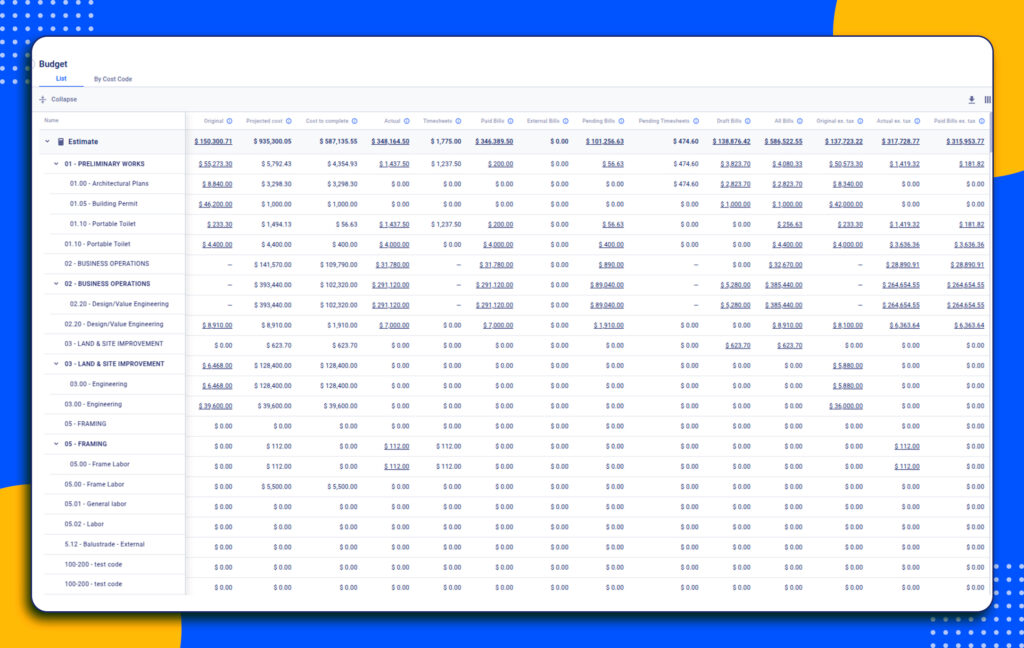

How to Manage and Track Construction Contingency

Now the harsh truth is that a well-set contingency only works if it is tracked with the same discipline as the rest of the budget. Many overruns happen not because the buffer was too small, but because the team lost visibility on how it was being used. Organizing contingency inside the job cost structure gives the project a clear place to record adjustments, justify decisions, and review how much risk remains as work progresses.

Centralizing Your Budget Structure

Start by giving contingency its own cost code. This keeps it separate from labor, materials, equipment, and other direct costs. When contingency sits inside another category, spending becomes harder to interpret later, especially during audits or owner reviews.

It is also important to keep the owner contingency and the contractor contingency distinct. Each one covers different risks and follows different approval paths. When the lines blur, teams find themselves having the same conversations twice because nobody remembers which buffer was meant for which issue.

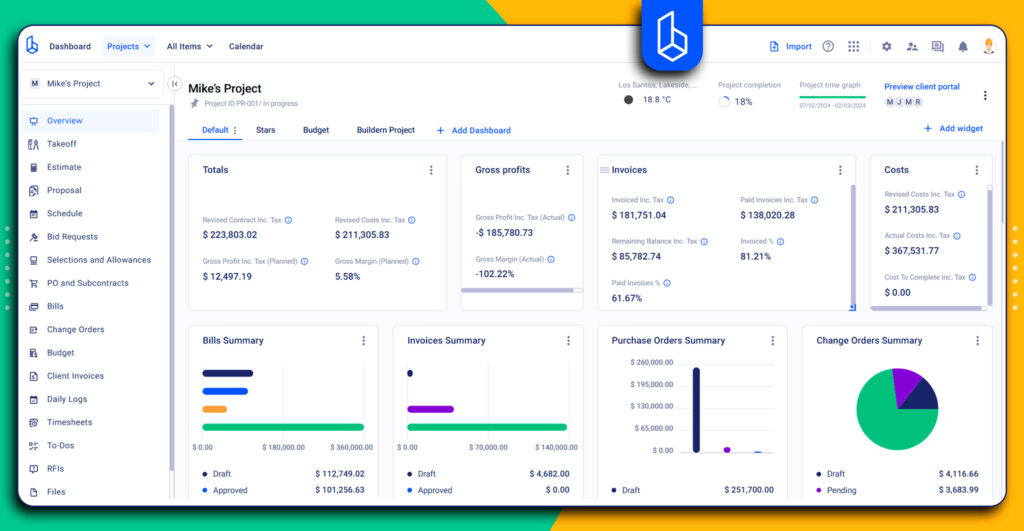

Using Digital Tools to Automate Tracking

Digital systems make contingency tracking easier, especially on projects with many moving parts. When the budget tracking happens in a central environment, the team no longer depends on scattered spreadsheets or outdated copies of cost reports.

A real-time dashboard can show how much contingency is still available and how recent changes affect the balance.

Linking purchase orders, invoices, and change orders to the correct contingency cost code keeps the record clean and prevents items from ending up in the wrong category.

How to Communicate Contingencies With Clients and Stakeholders

Contingency becomes far easier to manage when everyone understands its purpose from the start. Misunderstandings usually happen when owners treat it as optional or when the team feels pressured to justify every small use. Clear communication prevents this. It sets expectations early and keeps the project moving when real-world issues appear.

Setting Expectations During Preconstruction

The conversation about contingency should happen before any work starts. During preconstruction, the builder can explain how contingency fits into the overall budget and why it is necessary for the project’s stability. When this discussion is skipped, owners may assume the line item can be removed to lower the initial price. That almost always leads to tension later.

It helps to describe contingency as part of the planning logic, not an add-on. Some teams include a short explanation in the budget summary so stakeholders understand exactly why the buffer exists. This avoids the misconception that contingency is a pool of unused funds waiting to be reclaimed.

Showing Transparency in Usage

Once construction begins, transparency helps maintain trust. When the team uses contingency, documenting the reason makes the conversation easier. A short explanation tied to photos, test results, or field notes often removes any doubt about why the adjustment was necessary.

The goal is not to over-explain but to give the owner enough context to see that the cost aligns with the project’s risk profile. A consistent approach reduces back-and-forth and keeps decisions moving without delay.

Reporting Methods

A simple reporting structure is usually enough. Many builders present a short contingency summary every month, listing:

- The original contingency

- How much was used

- The remaining balance

- Upcoming risks or items that may draw from the buffer later

This format gives stakeholders a clear, predictable snapshot. It also helps everyone see whether the project is tracking comfortably or nearing the edge of its risk allowance.

Regular updates take the pressure off end-of-project conversations, because the financial story has been visible throughout the build.

Conclusion

Contingency is most effective when the team treats it as a structured part of the budget rather than something to revisit only when a problem appears. It gives the project room to handle the uncertainties that show up in almost every phase, from early design adjustments to field conditions that only become visible once work starts.

So remember that the right percentage depends on the project’s specific risks, the maturity of the documents, and how the contract distributes responsibility.

How Do I Calculate Contingency?

Many builders start with a risk review instead of a fixed percentage. They look at document completeness, soil conditions, project size, contract structure, and market volatility. These factors help determine whether the buffer should sit at the lower or higher end of the typical range.

Is Contingency the Same as Allowances?

No. Contingency covers unknown risks. Allowances cover items that are known but not fully specified or priced. Mixing these two categories makes it harder to track costs accurately.

What Happens When the Construction Contingency Is Not Enough?

If the buffer runs out, the project usually faces one of three outcomes: re-scoping, lowering material or finish quality, or opening a formal discussion with the owner about additional funding. A clear communication plan helps manage this situation, but the best approach is to set the contingency correctly from the start.