Construction Job Costing: A Smarter Way to Stay on Budget and Maximize Profits

Ever wondered where all the money goes in construction projects? Our industry doesn’t rely solely on winning bids, but also on how well you manage costs after the contract is signed.

From tracking labor and materials to identifying cost overruns before they spiral, construction job costing gives builders the clarity and control they need to make informed decisions throughout the project lifecycle.

Construction job costing serves as an important component of construction accounting, helping companies maximize their profit margin and ensure financial success for every project.

In this article, we will guide you through job costs in construction, explaining what they are and how they can help you ensure the financial stability and health of your construction project.

Table of Contents

- What is Job Costing in Construction?

- Job Costing vs. Process Costing

- Core Cost Categories and Granularity

- How to Calculate and Attribute Costs in Construction

- Benefits of Construction Job Costing

- Conclusion

What is Job Costing in Construction?

The term construction job costing initially refers to the process of accurately monitoring costs that are associated with a given construction project. It gives the complete picture of all the costs of your construction project, including labor, materials, equipment, and overheads. With job costing, you can easily track all expenditures and analyze them for future profitability.

💡Construction job costing serves as an important component of construction accounting, helping companies maximize their profit margin and ensure financial success for every project.

Companies lacking smoothly organized processes are left guessing where their money goes, and more often than not, this leads to missed opportunities.

Job Costing vs. Process Costing

While both job costing and process costing are methods used to track and allocate costs, they serve very different types of businesses.

Job costing refers to processes tailored to industries like construction, tracking all direct and indirect costs and helping builders evaluate the profitability of each job individually.

Process costing, on the other hand, is more common in manufacturing environments. It’s used when identical or similar products are produced in a continuous flow.

In short:

- Use process costing when you’re mass-producing consistent items in large batches.

- Use job costing when every project has its own blueprint and budget.

Core Cost Categories and Granularity

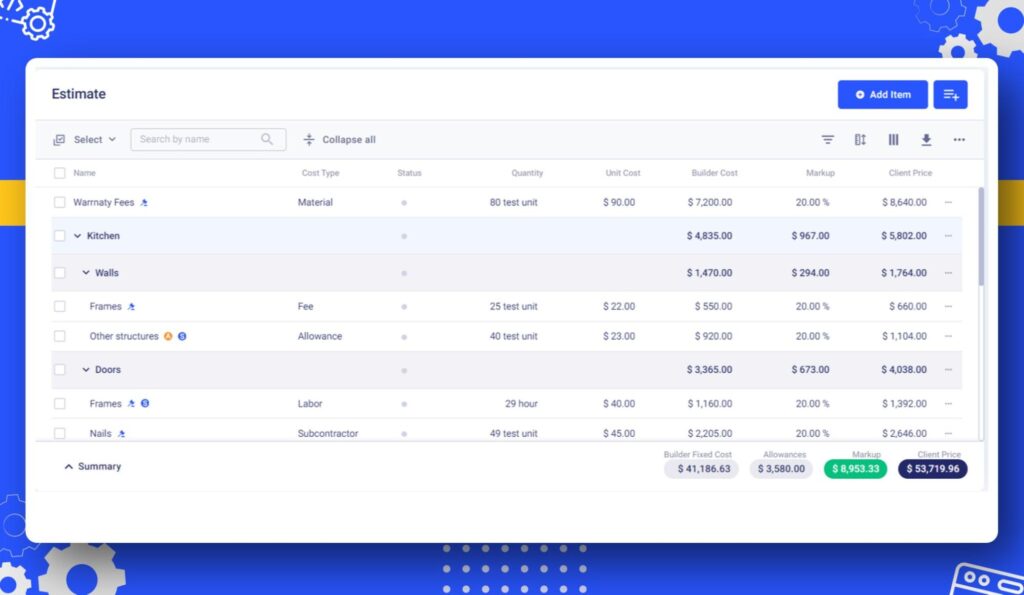

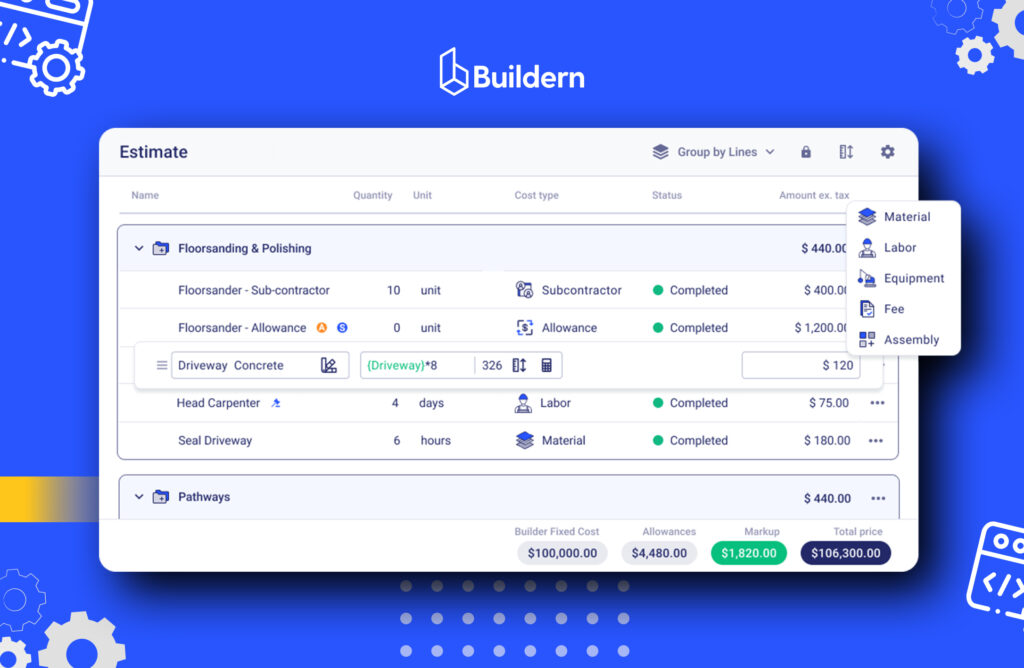

A key strength of job costing lies in its level of detail. Rather than lumping all expenses into a single bucket, job costing allows contractors to break down costs into specific categories and subcategories. This offers deep insights into how resources are used across each phase of the project.

At a high level, job costs in construction typically fall into three main categories:

- Labor: Wages, benefits, taxes, and overtime tied directly to a specific job.

- Materials: All physical building supplies purchased or used on a project.

- Equipment: Machinery, tools, and any related rental or maintenance costs.

Beyond these, many firms also track:

- Subcontractor expenses

- Permits, inspections, and fees

- Overhead allocations

The more granular you get into cost tracking, the more actionable your data becomes. Accurate breakdowns allow project managers to identify inefficiencies early and make smarter financial decisions moving forward.

Direct vs. Indirect Costs

Simply put, direct costs are tied specifically to one project and are the key processes, like delivering materials to the job site, counting the labor hours logged by your workers, or allocating equipment rental fees. These costs are easy to trace and allocate.

Indirect costs, also known as soft costs, refer to the non-physical expenses that are associated with the given construction project. Typical indirect costs include project management fees, permits and inspection fees, and legal and accounting fees. These costs are important constituents of construction job costing and can significantly affect a project’s financial viability.

Phase-Level vs. Job-Level Tracking

While tracking costs at the job level gives you a snapshot of overall profitability, phase-level tracking offers a much sharper view into how your project is performing at each stage.

Job-level tracking answers questions like:

- Are we over or under budget for the entire project?

- Is this job more or less profitable than others we’ve done?

Phase-level tracking, on the other hand, helps you:

- Spot issues early by comparing planned vs. actual costs in real time.

- Identify which phases (e.g., framing, HVAC, finishing) tend to go over budget.

- Improve future estimates based on past performance by project phase.

Here’s a visual representation of this for better understanding:

| Criteria | Job-Level Tracking | Phase-Level Tracking |

|---|---|---|

| Focus | Entire project as a single cost center | Individual phases or stages within a project |

| Detail Level | High-level overview | Granular breakdown by construction phase |

| Use Case | Assess overall job profitability | Identify cost variances within specific stages |

| Budget Control | Good for total budget monitoring | Better for spotting overruns early |

| Forecasting Accuracy | Less precise for future bids | Enables more accurate estimating based on phase performance |

| Issue Detection | Issues detected after project milestones | Issues detected in real-time, phase by phase |

| Ideal for | Smaller or less complex projects | Larger, multi-phase, or high-budget builds |

How to Calculate and Attribute Costs in Construction

Job costing is calculated by adding together costs for all the items categorized under the following areas of a project: labor, materials, and overhead. The overall formula for calculating the cost of a job is as follows:

Total Job Cost = Materials + Labor + Subcontractors Costs + Equipment Rental + Permits & Fees + Overheads

Material costs are calculated by summing all raw project materials, while also including material-related costs like delivery to the construction site. Labor costs are calculated by multiplying each worker’s day or hourly rate by how long the job takes.

Example of Job Costing in Construction

💡You can do all the calculations manually or simply add all your financial data to construction project management software and let it do the hard work for you.

Now, let’s suppose you are building the foundation for a house.

Materials: The total allocated money for all the materials is $15000.

Labor: There are three workers, each of them working 8 hours a day, and the hourly rate is $40. In that case, the labor cost will be 3 workers x 10 days x 8 hours x $40 = $9,600

Equipment rentals: $4,000

Permits and Fees: $2,500

Overhead costs: $2,000

Job Cost = $15,000 + $9,600 + $4,000 + $2,500 + $2,000 = $33,100

Benefits of Construction Job Costing

- Manage Budget: Job costing gives you more than just numbers. It gives you control by allowing you to compare actual costs against your estimates and get a real-time view of where your money is going. If something’s off-track, you’ll catch it early.

- Track Progress: When tied to your project milestones, job costing becomes a progress tracker. Going through each phase, you’ll know exactly how much work has been done, how much it’s costing you, and whether the timeline still holds. If something starts to slip, like delayed framing or stretched hours, you’ll spot it fast and correct the flow before it affects the next stage.

- Monitor Cash Flow: Forecasting your cash needs is one of the biggest winds of accurate job costing. With every cost tracked and accounted for, you’ll see when expenses will hit and how they align with incoming payments. This lets you plan disbursements, manage client billing cycles, and avoid last-minute cash crunches.

- Identify Issues and Track Efficiency: Breaking down your costs by task or phase improves your visibility and highlights inefficiencies. You’ll quickly spot where things are going off-track, whether it’s underperforming crews or overspending on materials. The result? Smarter decisions, fewer delays, and a tighter grip on your profit margins.

Conclusion

When done right, construction job costing gives you complete control over your money flow, as well as provides insights on how your projects perform and what needs to change to protect your margins.

By making job costing part of your day-to-day operations, you’re not just reacting to financial surprises, but staying ahead of them. It’s a strategic approach that reduces risk, sharpens your estimates, and helps you deliver profitable, well-managed projects every time.