5 Types of Construction Cost Estimation and How to Do It

The wise construction manager knows that the actual cost of any project is only realized once the task is complete and all financial obligations have been accounted for. That’s because too many predictable and unpredictable factors can affect the cost of a major construction project.

Meanwhile, however challenging the task of predicting the total cost of a construction project may be, one thing is sure: precise construction cost estimation from the start is an absolute must.

That said, what steps should a construction manager take in order to estimate the cost of any given project accurately? This article gives an extended answer to that question by detailing the steps involved in construction cost estimation.

Read on to learn more about the process.

Table of Contents

- What Is Construction Cost Estimating?

- Why Is Construction Cost Estimation Crucial?

- 5 Main Types of Construction Cost Estimates

- Conclusion

What Is Construction Cost Estimating?

In simple terms, the term refers to calculating the total expected cost of any construction project before it begins.

It includes all the components of a project, such as the labor, materials, permits, and other associated costs. A good estimation goes beyond the initial costs and considers possible problems and adjustments that may arise throughout the project’s life.

Typical cost estimation comprises two main components: direct and indirect costs.

- Direct costs are expenses related to the physical construction work, such as materials, labor, and subcontractor fees.

- Indirect costs include items like taxes, interest payments, insurance premiums, permits, etc., which may not be immediately apparent but must be accounted for to determine the total cost of the project.

Why Is Construction Cost Estimation Crucial?

Entering a construction project without properly estimating costs is a recipe for disaster.

Accurately predicting job costing will help ensure that it meets the budget set by owners and other stakeholders involved in the project. This greatly depends on the quality of information and data available to your estimators.

Of course, no one can estimate a project with 100% accuracy in such a complex field as construction. Weather changes, frequent cost fluctuations, and numerous other factors in the job site make construction one of the less predictable industries.

So, when we are talking about a good or an accurate estimation, we mean that an estimator accounted for as many factors as possible that could affect the construction process. A good estimation secures the project stakeholders from unexpected losses, which can happen if the expenses go beyond the construction budget.

The purpose of good estimation is to create a base for you to set rational contracts with your sub/vendors to get the materials needed to finish the job without any financial surprises.

When Should Builders Estimate the Construction Costs of the Project?

The sooner, the better.

Estimation shouldn’t come after the contract has started. Instead, it should be done before the project is awarded to ensure that parties involved understand the costs and budget associated with the job.

No property owner will enter into a contract where they are unsure if their budget is realistic, and no builder will want to be stuck with a project with costs beyond what the owner can afford.

5 Main Types of Construction Cost Estimates

There are 5 main types of cost estimations in construction, according to The American Society of Professional Estimators. These phases mainly differ in terms of the level of detail and accuracy, depending on the stage of the project and available data.

Let’s have a quick overview of each type.

#1 Order of Magnitude Estimate – Project Design Is Not Available Yet

The Order of Magnitude Estimate is used when the project design is not yet available. It is an early-stage estimate that provides a rough overview of the cost of the project, and it can help contractors determine if a project should continue forward or be pushed back.

This type of estimate is usually based on contractor experience along with available information about the project. It takes into account the scope of work, expected materials and labor costs, as well as any other factors that could affect the cost of construction.

#2 Schematic Design Estimate – Only the Schematic Design is Available

The Schematic Design Estimate is used when the project’s schematic design is available but the detailed design has not yet been completed. It takes into account more factors than an Order of Magnitude Estimate and provides a better idea of the construction costs.

The schematic design includes a basic layout of the project, such as the number and size of rooms and certain design elements. This type of design maps out the exterior, interior, and different structure systems, providing contractors with a more detailed overview of what resources they may need to complete the project.

#3 Design Development Estimate – The Initial Design is Available

The Design Development Estimate is used when the initial design of the project has been developed, and it takes into account more factors than a Schematic Design Estimate. It includes detailed information about materials, labor costs, and other factors that could affect the cost of construction.

This type of estimate requires contractors to dig deeper into the details of the project. It considers every element that could affect the cost and any potential changes that may need to be made along the way.

#4 Construction Document Estimate – Construction drawings are available

A construction document estimate is performed once blueprints and construction drawings are available. It considers all the details of the job, including the exact materials needed, labor costs, and any potential changes that may need to be made along the way.

Having construction drawings allows contractors to provide a more accurate estimate that factors in the actual size and shape of the building, as well as any other elements that could affect the cost.

This estimation phase can be considered almost final, as it is based on a detailed design and allows contractors to make informed decisions about the project.

#5 Bid Estimate – Construction documents are available

A construction bid estimate is the last step before the project is put out for bidding. It takes into account all the information gathered during the previous estimation phases and provides a detailed breakdown of estimated costs.

At this point, contractors have access to all the documents required for submitting bids and can make informed decisions based on the material and labor costs associated with each element of the job.

Bid estimates are used when bidding for projects and aim to provide contractors and investors with an accurate assessment of what the project will cost. The owner uses this estimate to compare different bids and choose the most favorable one for the job.

Which Components Go Into Construction Cost Estimate?

Before we list the main construction estimate components, it’s worth noting that construction estimation for different projects can vary. This is why it’s important to adhere to the specific requirements of your project and include all the necessary elements in the estimate.

With that said, here are some of the most common components used during construction cost estimation.

Labor Costs (Hour and Rate)

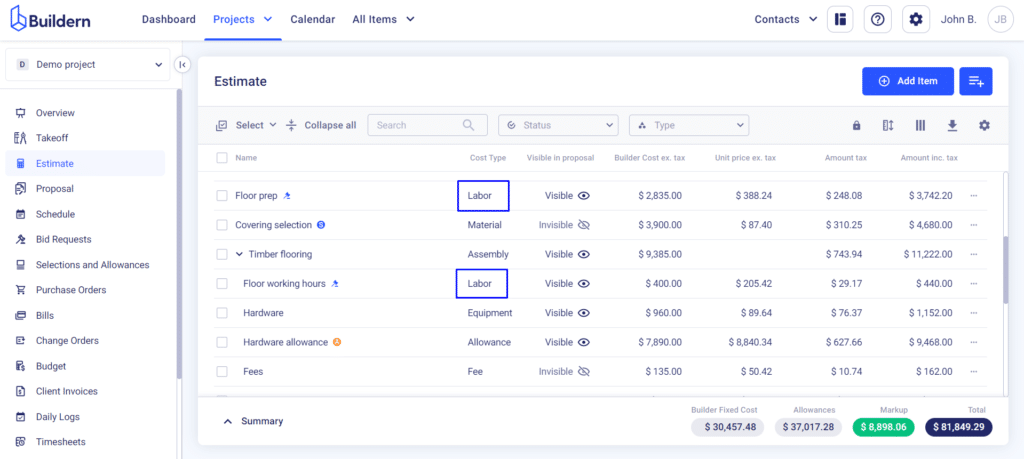

Labor costs comprise around 50% of the construction project, so this element is crucial to the estimate. This number should include both the hourly rate and hours required for each employee, including skilled and unskilled workers.

Provide your client with a detailed representation of man-hour rates to give a clear picture of the labor costs expected. If you plan to work with sub/vendors, ensure to include their rates as well.

Materials

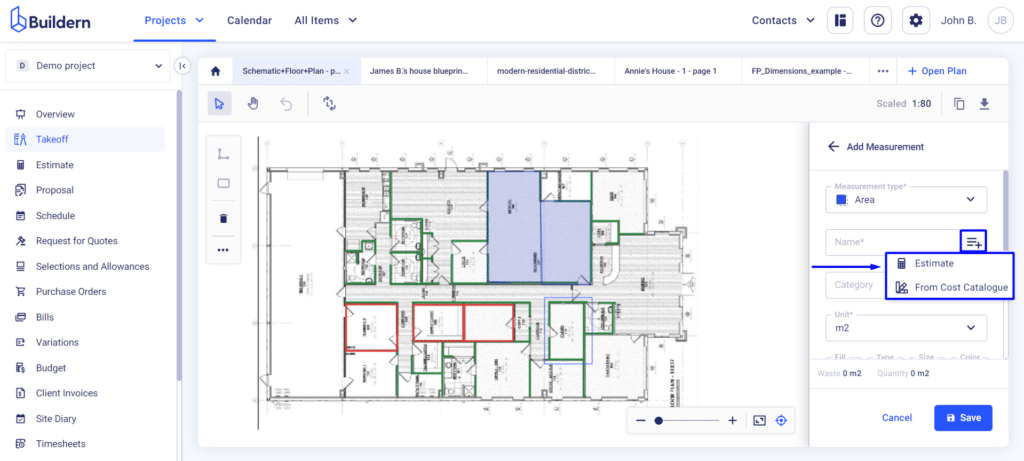

You may already have the estimated costs of the required materials from the takeoff process. As the latter is the preparatory step for detailed construction cost estimation, you should pay closer attention to the plans and measurements to avoid any miscalculations.

Working with construction project management provides an additional level of flexibility and all the tools to:

- Work with the count-type measurements to estimate the number of various material units;

- Work with materials with linear measurements that require precise length calculations;

- Measure elements with two-dimensional calculations;

- Work with materials that need to be measured in volume like asphalt or concrete.

A crucial tip here is to leave space for a potential increase in material costs, as prices can vary significantly during the project. Materials prices are often subject to fluctuations in the construction industry, where projects usually last for more than a year. Meanwhile, you can’t stockpile all the construction materials in advance, so the cost fluctuations don’t affect the project cost.

So, however challenging the prediction of material price fluctuations may be, try to include this element in the construction cost estimate.

Equipment

The equipment section should include any cost associated with owning or leasing construction equipment, as well as costs of transporting and securing the equipment.

In some cases, it may be more rational to rent equipment instead of buying it. Depending on the size of your project, it can save a lot of money in the long run – which is why estimators need to include all the possible options when deciding on the type and cost of construction equipment.

Leasing equipment is usually a good choice when the construction site is far away from the company’s location, and transportation costs will outweigh the rental costs. It’s also a good choice if the project requires specialized equipment, which will not be used often for other projects of the builder. In this case, as compared to buying it, renting will be much more cost-efficient.

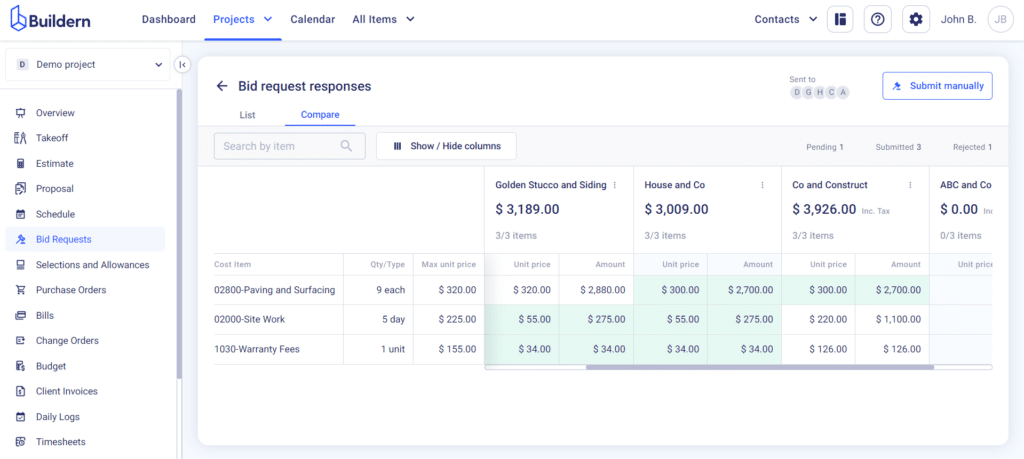

Sub/Vendor Quotes

There may be cases when you need to include sub/vendor quotes in the estimate. These should include all the necessary labor and material costs associated with the sub/vendor’s project work. If you’re planning to outsource a part of the project to another contractor, ensure to do thorough research and choose a reliable partner to cover specific project parts.

An important tip here is to ensure you initially receive a quote from your sub/vendors, which includes both labor and materials. This helps avoid any potential cost overran later in the project.

In this regard, building a solid network of sub/vendors you can trust and rely on is crucial. You may also want to have a place where you manage your work with them, implement bid leveling and have all the job-related data securely stored.

With a reliable network of sub/vendors, this section of your construction estimation will be more predictable and easier to manage.

Indirect Costs

Construction is not only about materials and labor but also about the additional costs that go along with it. This includes anything from fees to taxes, insurance and administrative fees.

Indirect costs can add up quickly, so estimators should take their time assessing them and ensuring all the expenses are appropriately listed in the construction estimating document.

If you miss indirect costs during the estimation process, it can lead to significant budget overran later in the project. This is why you need to keep track of all the additional costs and ensure they are properly accounted for.

Escalation

Escalation in construction is the increase in cost due to inflation, currency fluctuations or other market factors. It’s important to account for this element in your construction estimation document as it can significantly impact the final project budget.

An escalation component in your contract secures you from budget overruns, implying that if prices rise, the project cost will still be covered and contract terms will be adjusted.

Contingencies

Contingencies and allowances should be built into the construction estimation document to account for unforeseen expenses during the construction. In other words, it’s an extra budget that can be used in case something unexpected happens and you need to buy additional materials, hire more people, or make other unplanned expenses.

An industry standard for risk contingency is 1-3% of the project’s hard costs. However, depending on the mutual agreement with the owner, you can also adjust the contingency amount, including some percentage of soft costs as well.

A contingency reserve can also pay builders extra incentives or bonuses if the project is completed on time and within budget.

💡Recommended Reading

3 Main Estimating Approaches

Here’s how you can approach the construction cost estimation process:

Unit Pricing

Unit pricing is best for estimating direct costs, which can be easily measured and compared, such as materials and labor costs. To estimate a construction project with a unit pricing method, you need to have a library of specific unit costs for each element.

These are called Cost Codes and help construction industry players easily identify different materials and labor costs. Suppose, codes started with 01 are General Requirements, 11 are for Equipments, and so on.

For unit pricing estimation, the builder must have a particular element’s required quantity during the construction project and unit cost to make the total estimate. For example, if a contractor needs to know how much it’ll cost to build a 3-meter wall and knows the unit cost of the 1-square foot wall is $10, then they can make an accurate estimation.

Square Footage Pricing

The square footage pricing method is a dirty estimate approach. It means the estimator should use the most basic calculations based on the square footage of the built project and then add a percentage to that to account for additional costs. In this case, the estimator uses the total floor area or building size as the base number and adds some percentage based on previous experiences.

This is a fast and easy approach for rough estimation that does not require much work on the builder’s side. This method is often used when there is a need for quick proposals and you do not have enough time to do an in-depth analysis.

After the rough estimate, builders and owners get into detailed discussions, and more accurate estimations are made. So, there is no need to be afraid of starting a project without a detailed estimation and then experiencing financial losses.

The Rule of Two

The Rule of Two is based on the idea that labor costs account for around half of construction projects. So, if builders can roughly estimate the man-hours needed for the project, they can double that number to get a rough estimation of the total costs.

For instance, if a builder suggests it takes 10 man-hours to complete a particular task or group of tasks, the estimated cost will be twice as much (20 man-hours).

However, there should also be a profit margin and some reserved contingency budget in case of unexpected costs. This number is usually 10% of the doubled labor costs in the Rule of Two methods.

Conclusion

Having as precise an estimate as possible is crucial for accurate and easy construction accounting. Obtaining precision in estimates, you get one step closer to streamlining your construction workflows and establishing yourself as an authoritative industry player.

You can take this even further if you start managing your projects with advanced estimating and construction management software.

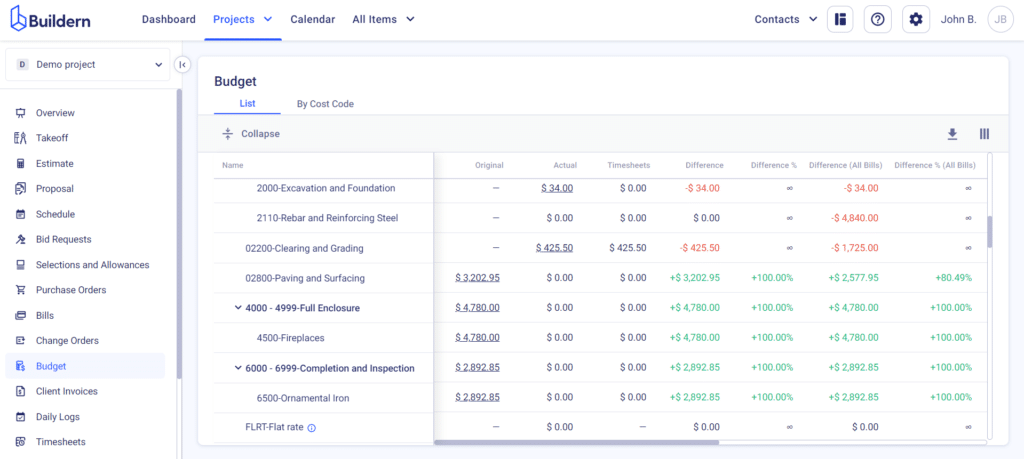

Buildern can help you cut unexpected project costs by 15% and reduce the overall project completion time by more than 20%. This is possible due to the software’s advanced features such as automated cost calculations, efficient data management, and communication with your team members, sub/vendors, and clients.

So, while rough estimates are a good starting point, utilizing technology can significantly improve your accuracy and efficiency.

Sign up to start your free trial and see how Buildern can transform your construction projects today!