7 Construction Technology Trends You Cannot Miss

Updated in October 2025

The construction industry is one of the world’s largest and most influential sectors. It’s not static, and the construction volume as well as annual output may differ in a year-to-year perspective.

Just as in any other industry, one cannot imagine the future of construction without the use of AI and modern devices.

Digital transformation is huge in the industry, and more people use automation to streamline their processes. This refers to every field, from large commercial construction companies to general contractors using construction management software.

In this article, I will highlight 10 construction technology trends shaping 2026. They are not just predictions, but the innovations I see the companies are using to be ahead of their competitors.

Table of Contents

- Trend #1 Cloud-Based Construction Software and Mobile Apps

- Trend #2 AI & Machine Learning In Construction

- Trend #3 Drones

- Trend #4 Green Construction Technology

- Trend #5 3D Printing

- Trend #6 Robotics in Construction

- Trend #7 IoT and Advanced Analytics

- Final Thoughts

Trend #1 Cloud-Based Construction Software and Mobile Apps

Construction companies often face time management issues. Cloud-based construction software platforms help in solving these problems.

According to some estimates, the construction industry represents roughly 13% of global GDP. Besides, it’s an industry that employs millions of people. Thus, construction technology trends affect thousands of professionals.

However, the construction industry has been traditionally one of the least digitized industries in the world. However, it has been changing. Many construction firms have started using software and mobile apps to track their tasks to tackle this issue.

Of course, tracking the workflows via Excel or paper documents is still possible. Yet, it’s almost impossible to imagine how someone can sit and write all the data of a large construction project on a piece of paper, let alone client invoicing and accounting documents. Instead, cloud-based software offers more scalability and improved accuracy.

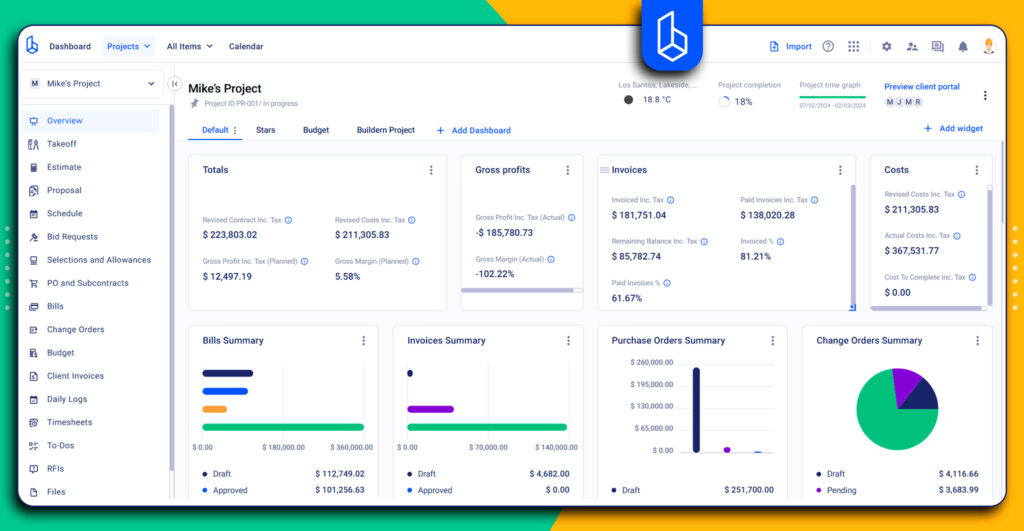

Based on my experience, if you want to avoid management problems and budget overflows, it’s better to start using cloud-based tools that assist in construction project management.

But to understand why your company needs it, you first need to realize what it is.

How Can Cloud-Based Tools Benefit You

Cloud-based computing is the technology that allows users to access data through a software application that operates using the same shared computing resources.

What does this mean for a construction company? It means you and all the project stakeholders can access real-time data from their devices.

The cloud-based software allows company employees to submit their reports, time cards, and RFIs from the working site. This means the software organizes all the information automatically, saving construction managers hours of work.

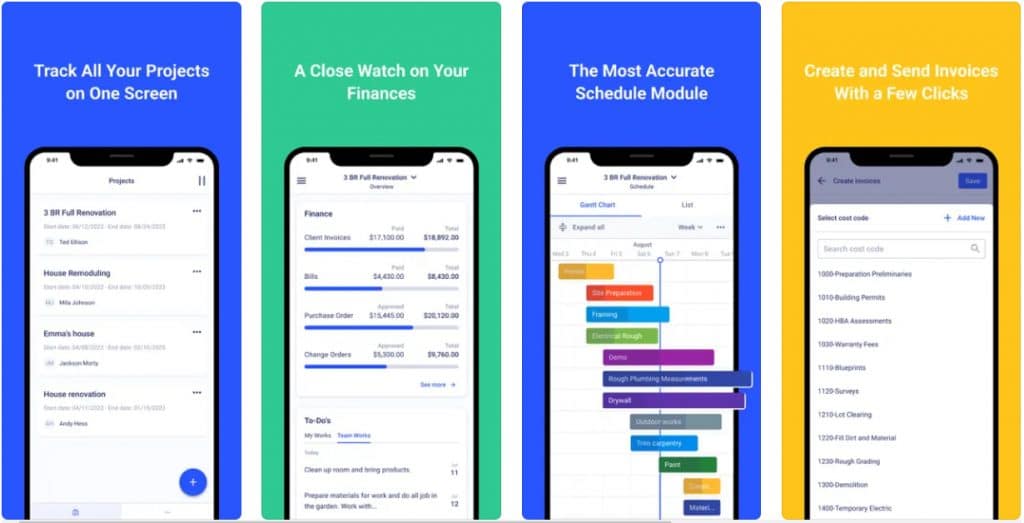

On the other hand, I cannot imagine my work without a mobile phone. Software with mobile applications helps builders manage every single detail of their construction project. It all starts with estimates, proposal generation, tracking schedules, and also includes communication tools to avoid numerous chats in different apps.

What Features to Choose?

Construction is a big industry, and a specific niche should choose the tool that will best fit its goals.

Depending on the type of your business, you should opt for a platform that can:

- Sync with any other type of software (e.g., accounting) and provide you with a big-picture view

- Support various stages of the construction project (both on desktop and mobile)

- Help you design detailed takeoffs, estimates, and reports

- Communicate with all project stakeholders via the sub and vendor portal in real time, providing them access to critical information.

Trend #2 AI & Machine Learning In Construction

Why force your employees to engage in repeated manual tasks if you can avoid it with the help of artificial intelligence? Just think about the time your workers waste copying invoices and following other aspects of the construction workflow.

In 2026, AI has gone far beyond simple automation. It’s now a core driver of decision-making, efficiency, and profitability in construction. What once sounded futuristic is now an integral part of the daily workflows across the industry.

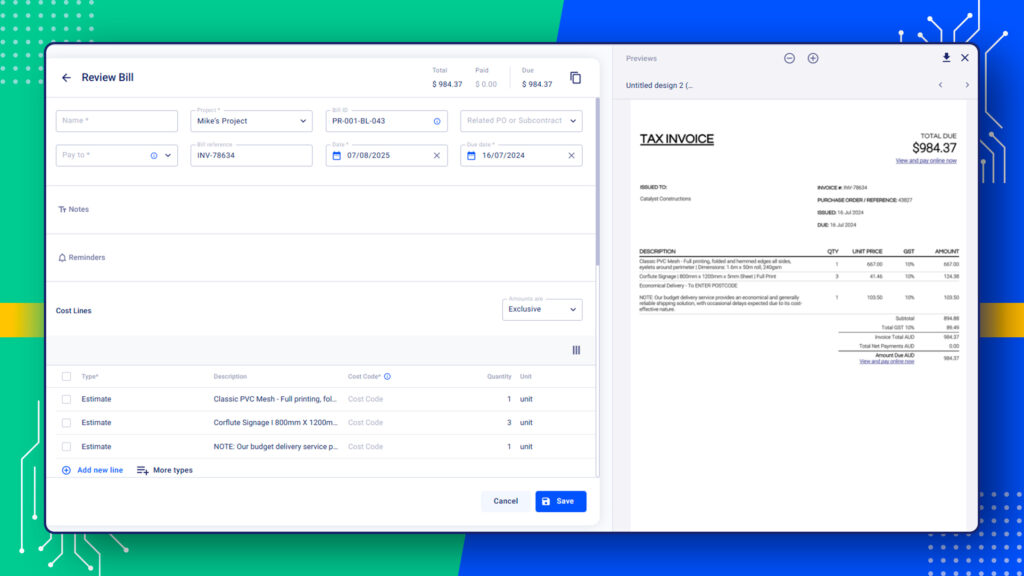

For example, the one tool I personally use is AI when dealing with invoices. Tools like AI Billing automatically process receipts, validate line items, and match invoices against project budgets. This eliminates hours of manual work and ensures errors are caught before they lead to costly disputes.

But AI isn’t limited to billing. Construction firms are also adopting it for project planning, like analyzing historical data and current site conditions to forecast risks, delays, and resource shortages.

AI-powered estimating can also save much time. For example, pulling data from past projects, to deliver highly accurate cost projections, reducing the risk of underbidding or budget overruns, may also work with he help of artificial intelligence.

💡You can pull data from an invoice in a few clicks using Buildern.

Using AI in construction has become popular in recent years for many companies. However, in my view, AI use will increase through many projects to bring much more automation, which is great news.

Trend #3 Drones

Drones are no longer a “trend” in construction but a standard tool. It all started a decade ago as an experimental way to capture aerial photos. However, now it has grown into a critical technology used daily across job sites worldwide.

Construction firms now rely on drones for site surveying, progress tracking, and safety inspections. They are usually equipped with high-resolution cameras and LiDAR sensors. Drones can quickly create detailed 3D maps and digital twins of a site.

These tasks usually take me days or even weeks, while maps help project managers monitor grading, earthwork, and structural alignment with unmatched accuracy.

Monitoring in Real Time

Beyond surveying, drones also do real-time monitoring. Project managers can oversee multiple job sites without leaving the office, while stakeholders receive visual updates on progress.

Construction safety is another major area where drones are used. Instead of sending workers into hazardous zones, drones can perform inspections and identify risks. This shift has significantly reduced workplace accidents.

Besides, the adoption of drones in construction is accelerating thanks to AI-driven analytics. The future is less about whether drones should be used and more about how to integrate them into existing workflows for maximum efficiency.

And that leads us to the next question. Should a construction company invest in drones and train its workers to learn the technology, or should it outsource drone services?

This is a serious decision; the answer depends on your company’s current situation. It was something I was thinking about. However, even having enough workforce and financial resources to buy drones does not guarantee that investing in your drone fleet is the best solution. This is because your employees might take too long to learn how to use the technology correctly.

So most of the time, outsourcing this critical task to a company with expertise in the sphere is the most efficient solution. But again, it’s a decision you should make on your own, considering all the advantages and drawbacks of outsourcing.

Trend #4 Green Construction Technology

Green construction technology is now a regulatory requirement and industry standard. Governments introduce stricter net-zero targets, and developers face stricter ESG reporting standards. This shift is pushing the industry to rethink how buildings are designed, constructed, and operated.

One of the most important developments I’ve seen is the growing use of cross-laminated timber (CLT). It’s a strong and lightweight wood panel product made from gluing together layers of lumber. CLT is proving itself as a viable alternative to concrete and steel in large-scale projects. Its adoption lowers the carbon footprint of construction and reduces build times.

At the same time, the ways the buildings consume and conserve power are changing. Smarter HVAC solutions, adaptive lighting, and improved insulation materials bring new efficiency levels. These systems are often paired with AI-driven simulations and IoT sensors, giving contractors real-time insights into a building’s performance.

There are also more green roofs and living walls in cities to improve air quality. This comes with modular construction methods. As a result, there is less waste, and sustainability is being embedded into both the structure and the process of construction.

Finally, renewable energy integration is becoming the standard. Solar panels, microturbines, and advanced battery systems are also parts of the design phase.

Trend 5# 3D Printing

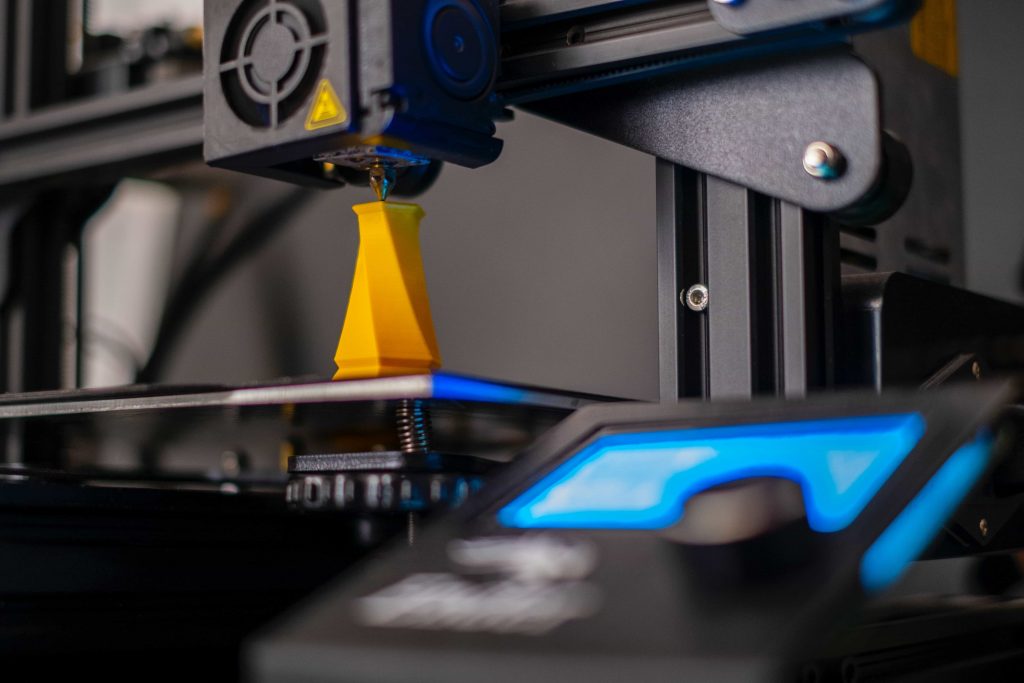

During recent years, 3D printing has shifted from being an experimental concept to a viable construction method.

I also used to view it as a futuristic concept, but not anymore. Now, full-scale additive manufacturing is being applied to real projects worldwide. Thus, 3D printing is also one of the technologies that redefine how buildings are designed and delivered.

The principle remains the same: structures are created layer by layer from a digital model. Different materials are used, including concrete, polymers, or composites.

However, what has changed in recent years is the scale and efficiency. Printers are now capable of producing entire walls, facades, and even complete homes.

This leads to less material waste, lower labor requirements, and a more sustainable building process compared to traditional methods.

It’s also a tool that governments and developers use to solve such problems as housing shortages. Thus, developers can build high-quality but affordable homes in much less time usually required for conventional construction.

Advances in printable materials are also pushing the trend forward. 3D printing goes hand in hand with the goals of green construction technology. Innovations span from carbon-neutral concrete mixes to recyclable composites.

Trend #6 Robotics in Construction

Robots used to be assistants when it came to repetitive tasks such as bricklaying or rebar tying. The technology has advanced into autonomous heavy machinery, site monitoring systems, and precision fabrication tools.

Autonomous excavators, bulldozers, and loaders are increasingly being deployed on job sites. They can grade land, move earth, or perform demolition with minimal human intervention.

These machines are guided by AI, GPS, and sensor technologies that allow them to operate safely and efficiently. This speeds up work and, most importantly, reduces accidents by removing workers from hazardous zones.

Besides, they play a key role in site monitoring and data collection. Mobile robots equipped with cameras and sensors can patrol construction sites and capture real-time progress. If a robot scans the site for risks, managers can make faster, evidence-based decisions without being physically present at the site.

I do not mean people are not working at all, as robots work alongside crews. Robots take over dangerous activities while leaving supervision, problem-solving, and fine adjustments to skilled workers.

Trend #7 IoT and Advanced Analytics

The Internet of Things (IoT) refers to networks of connected devices equipped with sensors, software, and connectivity. The goal is to collect and exchange data in real time.

Such devices as smart helmets and biometric vests, GPS wristbands, and equipment trackers are used to improve safety and efficiency on-site.

Wearables equipped with biometric sensors monitor vital signs such as heart rate, body temperature, and other indicators. They alert workers and field supervisors if conditions become hazardous, for example, if there are toxic gases or extreme heat.

I happened to see how AI tools are used to have this data preserved and stored. Advanced analytics amplify the value of this data. Once uploaded to the cloud, AI-powered dashboards provide project managers with a real-time overview of site conditions.

What Are the Top Construction Technology Trends for Builders?

The top construction technology trends in 2026 focus on making projects smarter and more sustainable.

The technology trends include:

- AI

- 3D printing

- green practices

- IoT and advanced analytics

Builders are increasingly using AI and advanced analytics. Everything that can improve operations and reduce human errors is popular. If one asks what is trendy in construction, I would definitely say it’s a practice targeted at improving efficiency, speeding up delivery, and reducing waste as much as possible.

How is AI Used in Construction?

AI is steadily becoming a core part of modern project management. While once it used to be like a tool of the future, it’s a part of the regular workflow. However, since the technology is developing and more applications of AI are emerging every day, it can be called a trend. On the operational side, AI supports automated reporting, billing, and document management, saving time and eliminating repetitive manual tasks for the builders.

How Technology Is Changing the Construction Industry?

The construction process involves many stakeholders and many risks. Technology is changing construction to make projects faster and safer. This involves all areas from planning and minimizing the risk of hazards on the site to improving collaboration and communication. After all, it’s not possible to stay competitive. While you think about introducing something new, other builders already use technology to speed up operations and outpace you.

Final Thoughts

Technology is developing fast, and companies in many areas have to adapt to the modern AI tools and IoT-enabled devices. Builders now have a wide range of tools to improve efficiency, safety, and sustainability on the job site.

Staying ahead of competitors is no longer just about having skilled labor. Without using construction management software and other technologies, you are hardly competitive in the market. Builders who integrate these construction technology trends into their operations are better positioned to navigate the unpredictable economy and achieve long-term growth.